- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Chemically Produced Toner

Chemically Produced Toner

Summary

Toner is a powder used for photo copying machines and laser printers that enables the printing of text, images and graphics on paper. In the initial stages of development, carbon powder was used, but this gave way to the use of melt kneaded carbon and polymer as a method to improve the print quality. Toner particles are melt and set on to the paper by the heat of the copying machine.

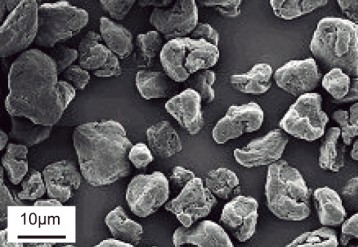

Generally, toner (Ground Toner) is produced in a process starting with the metering of the feed material, mixing, kneading, cooling, coarse milling, fine milling, classifying, post blending, sieving and filling. Over time the particle sizes and shapes have changed. Originally toner particle sizes were around 14 - 16 μm, sometimes even larger. As the requirement for higher definition of the prints increased, the particle size requirement became smaller. Currently for a 1200dpi print, the required toner size is around 5 - 8 μm.

Important Characteristics

-Particle size distribution

-Particle shape

-Electrical resistance

-Bulk density

Contents

Chemically Produced Toner (Polymerized Toner)

Fig.1 SEM of Traditional ground toner

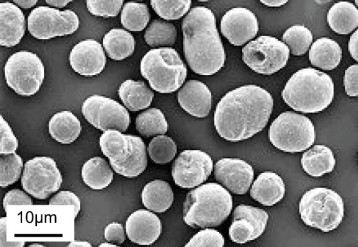

To obtain higher definition prints, toner particles are produced using polymerization. This is to obtain higher quality toner with particles that have uniform size and shape, enabling more accurate color reproduction. Also by using the chemical technology of polymerization, research and development on the melt properties of toner particles is progressing.

For chemically produced toner, a liquid-solid separation process is required after polymerization. The wet cake, which is the feed material, needs to be washed so the level of remaining materials is at a very low level. After washing and dewatering, the remaining water (approximately 30-40%) has to be reduced to about 0.5% W.B. without heating over the glass transition temperature of the toner.The polymerization process determines the particle size.

Requirements

Fig.2 SEM of Chemical (Polymerized) toner

- Dry from 30-40%W.B to 0.5%W.B.

- Dry at a temperature below 45ºC

- Particle size is less than 7 μm and shape is not changed

- Additive mixing to control the flowability and electrostatic charge

Solutions (Drying of chemically produced toner)

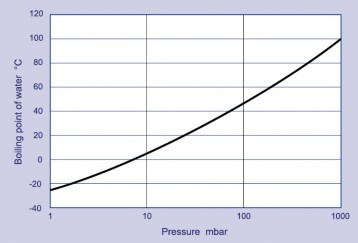

Fig.3 Boiling temp. of water

A Batch type vacuum dryer is used to lower the water content from 40% to 0.5% while at a low temperature. Milled toner has a glass transition temperature below 60ºC but chemically produced toner has an even lower temperature. To prevent degradation, drying at a low temperature is required.

Under atmospheric pressure, water evaporates at 100ºC, but by reduced pressure, the boiling temperature is lower. At 100mbar the boiling temperature is 46ºC; at 10mbar it is 5ºC. To control the material temperature below 30ºC a vacuum dryer needs to control the temperature with a heated jacket while the boiling point is lowered below this temperature by controlling the vacuum in the vessel.

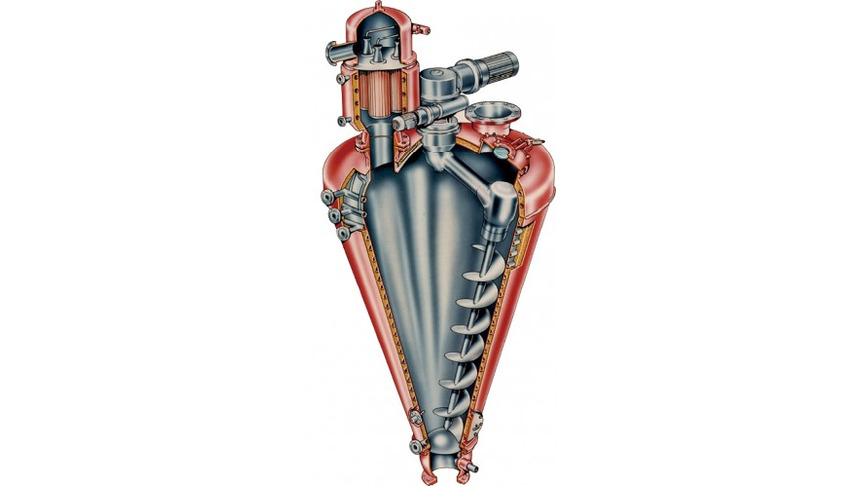

The Vrieco Nauta Vacuum Dryer can dry material at low temperatures with an optimum level of vacuum while preventing melting and agglomerate formation. Chemically produced toner (CPT; polymerized toner) is a heat sensitive material and localized heating must be avoided.

For the drying of chemically produced toner, Vrieco Nauta Vacuum Dryers of up to 20m3 have been delivered.

Drying time is determined by the following factors

- Level of vacuum during drying

- Jacket wall surface temperature

- Heat transfer coefficient between the jacket wall and material

- Heat transfer area

- Feed moisture content and product moisture content

Drying time is dependant upon the feed material amount and heat transfer area.

Fluidized Bed Dryer Agglomaster

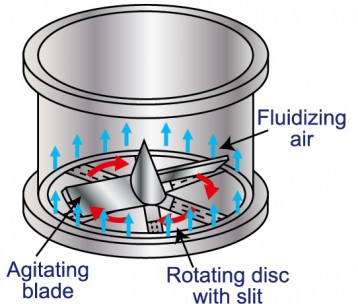

If the glass transition temperature of the polymer used in the toner is high, a fluidized bed dryer can be used. The Agglomaster PJ is a fluidized bed dryer with an opposing pulsed jet function that can break up agglomerates that form during the drying process.

Fig.4 Schematic figure of pulsejet dispersion

Fig.5 Agglomaster AGM-35PJ

Post Blending of Toner

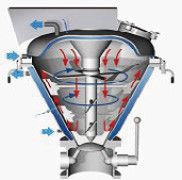

Fig.6 Schematic structure of Cyclomix

The high-speed high shear mixer Cyclomix mixes the dried cohesive toner with a small amount of flow control agent and stabilizer. The high shear mixing action rotates the toner and additive particles along the wall of the Cyclomix dispersing the particles and allowing the additives to coat the toner particles evenly. The Cyclomix casing and top cover are cooled with a cooling jacket and the specially designed shaft seal prevents material buildup. For milled toner with a harder polymer, the Nobilta is increasingly used for additive mixing.

Conclusion

Fig.7 Nobilta NOB-450

The Vrieco Nauta Vacuum Dryer can dry large volumes of chemically produced toner (polymerized toner) at the required low temperatures. With the high level of vacuum lowering the boiling point of water, the material is not heated and does not affect the shape of the toner. Additive mixing with the Cyclomix and Nobilta achieves an even coating of material without heating. Use of this equipment allows the production of toner particles with the flowability and electrostatic charge required for printing.

Related equipments

Feel free to contact us. if you have any questions or concerns.