- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- SiC Powder for Diesel Particle Filter DPF

SiC Powder for Diesel Particle Filter DPF

Summary

As a serious social problem, the regulation on the air pollution from fine particles of nitrogen oxides (NOx) exhausted from diesel engines has been tightened. DPF (Diesel Particle Filter) has been developed for the solution of this problem. DPF is constantly exposed to very high temperature of exhaust gas and should be regularly cleaned by heating up to 450°C. So material such like SiC, having very stable nature under high temperature are suited. DPF is made by press-formation SiC compound. Raw material of ceramics (matrics) consists of fine particles with precisely controlled particle size distribution. There are wet milling process and dry milling process in the industry. Hosokawa introduces a dryer for wet milled SiC and dry grinding system.

Contents

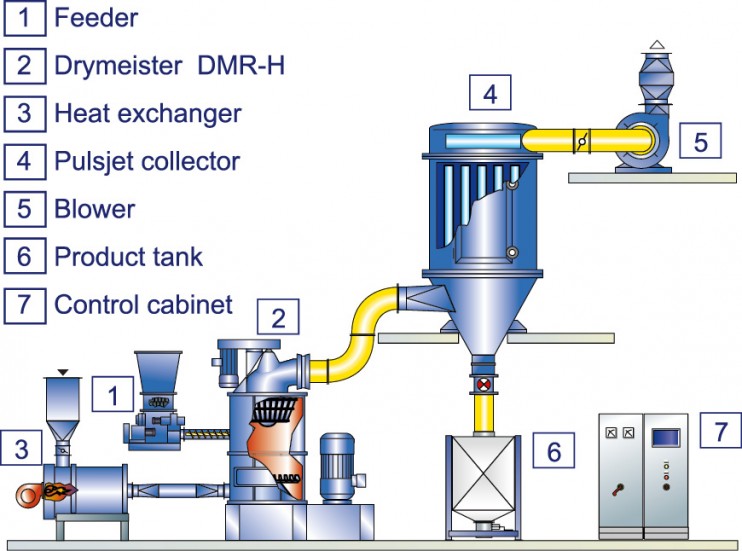

Drying

Ceramic material for DPF (such like SiC) is wet ground, dewarted by filter press and then dried. The drying is done by direct heating flash dryer, the Drymeister.

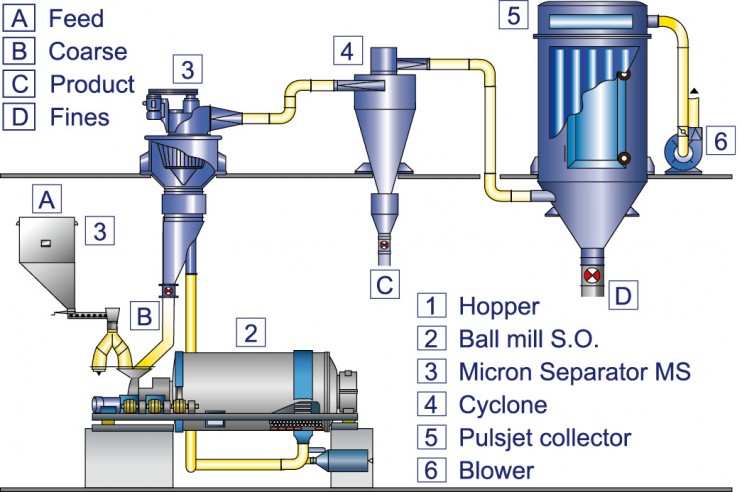

Grinding and Classifying

Fig.1 Micron Separator MS-2H

Among various characteristics, particle size distribution is the most important for SiC compound for filters. This SiC compound is sometimes fine-ground by the closed circuit grinding system with ball mill and air classifier. A classifier classifies ground particles by the ball mill, fines are removed from the circuit and coarse is returned to the mill for further grinding.

Fig.2 SiC drying system

Fig.3 SiC closed loop grinding system

Related equipments

Feel free to contact us. if you have any questions or concerns.