- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Exhaust Gas Treatment Sodium Bicarbonate (Baking Soda)

Exhaust Gas Treatment Sodium Bicarbonate (Baking Soda)

Summary

Acid gases such as Hydrogen Chloride (HCl) and Sulphur Oxides (SOx) that are generated from municipal incinerator will cause air pollution and acid rain. Therefore, for the environmental protection and pollution control - exhaust gas treatment is generally carried out by neutralization of the gas with caustic soda spraying in the wet scrubber. Plant cost and treatment of waste liquid are usually the main issues with this. For an alternative dry treatment using slaked lime, which does not produce waste liquid is often considered a solution. However, reaction rate of this method is low compared to wet method and it requires large quantities of slaked lime, so it has a disadvantage with the increase of waste materials. Exhaust gas treatments with sodium bicarbonate, which have much higher reactivity than slaked lime become more prevalent.

Contents

ACM Pulverizer

Making smaller particle sizes to increase the surface area is required to make best use of the production capacity of the exhaust gas treatment by sodium bicarbonate. To remove 99% of the hydrogen chloride and 95% of sulphur oxides from exhaust gas, it is necessary to use sodium bicarbonate powder with particle size distribution of 90% below 45 μm and 50% below 20 μm. However, when the ground power is stored in atmosphere, it will adsorb the moisture in the air and be solidified which makes it unusable. Product in the market is controlled as d90 = 0.3 mm to prevent from adsorption of moisture during storage. This has to be milled just before the use in the incineration plant. We offer the grinding system with the ACM Pulverizer having the features of small installation area, continuous operation as well as easy disassembling and cleaning.

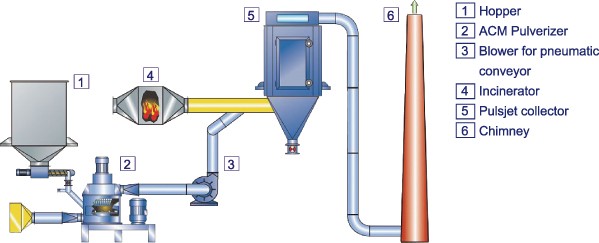

Fig.1 Flow of exhaust gas treatment

Exhaust gas treatment process (Fig.1)

- Constant feeding of the sodium bicarbonate from the hopper to the mill

- Grinds down to the required particle size with the pulverizer with integrated classifier.

- Transport the milled product by pneumatic conveying blower to the incineration gas flow

- Collects the reacted salt with dust by Pulsjet collector

- Exhausts only the cleaned gas into the atmosphere

Powderplex APP

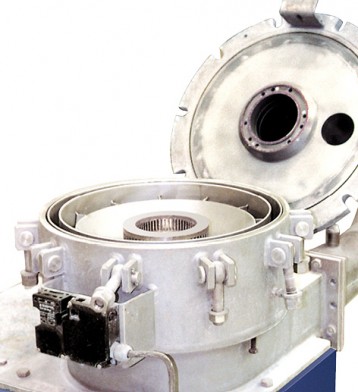

Depending on the incinerator size, the required quantity of the sodium bicarbonate needed to process the exhaust gas is different. Due to the product’s nature, sticking on the internals of the mill is unavoidable. It is necessary to clean the mill regularly to maintain grinding performance. We supply the specially designed grinding system for the treatment of the incineration gas, offering easy cleaning and low electric consumption. Powderplex is the mill modified from ACM Pulverizer for the treatment of the exhaust gas. The grinding rotor and classifying wheel are on the same shaft, enabling simplification of the bearing section, which gives high durability. More than 100 grinding systems for sodium bicarbonate have been delivered worldwide, contributing the air pollution control.

Fig.2 Powderplex 160APP

Related equipments

Feel free to contact us. if you have any questions or concerns.