- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Fire Retardant

Fire Retardant

Summary

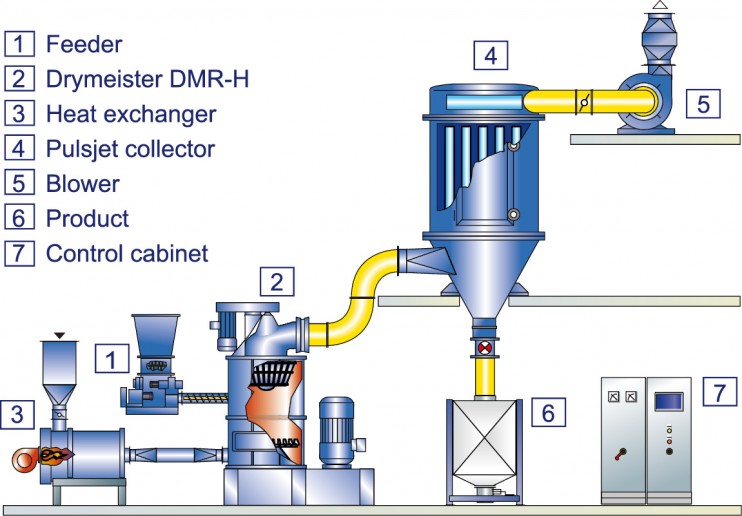

Fire retardant makes otherwise combustible material difficult to burn and avoids the flame spreading, it is achieved by kneading with plastic and rubber or coating on the textile and paper. Here introduces the direct heating flash dryer, Drymeister DMR-H type for grinding/drying of the magnesium hydroxides, which is used as fire retardant for the engineering plastics of the covering material of electric wires, wallpaper, floor material, and putty material.

Contents

Fig.1 Drymeister DMR-1H

For the drying and grinding of magnesium hydroxides, it is required to dry wet cake with high moisture content and to disintegrate up to nearly primary particle size.

Rotary kilns or belt dryers had been conventionally used for dry the material, and then disintegration is conducted separately with the impact mill. In the Drymeister system, it is possible to execute drying and grinding process at the same time.

In DMR-H system, it is possible to use the inlet air temperature up to 600°C to dry the material. This big heat energy created by the temperature difference between the inlet and outlet (normally 100°C) can be utilized for drying the wet material. Replacing the dryer main body with setting high inlet temperature and without change of the ancillary equipment, there is a possibility to increase drying capacities. Comparing with the combination of rotary kilns and impact mill the total process time of DMR system can be shortened dramatically. Less equipment is needed so the plant can be designed to be very compact.

This process can be utilized in the magnesium carbonate, which is used in the food additives as synthetic expansion agent, natural rubber, various synthetic rubber and additives for paints.

Fig.2 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.