- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Fillers and Pigments for the Paper Industry

Fillers and Pigments for the Paper Industry

Summary

Pigments for the paper industry

The quality demands with respect to most types of paper are steadily rising. Higher brightness, higher opacity and better printability at constant or improved running properties with ever-faster paper coating machines are just a few of the criteria. These demands – combined with the trend towards increasing the amount of paper fillers – pose a great challenge to the manufacturers of pigments for paper.

Contents

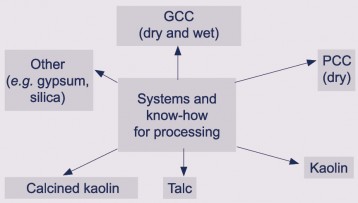

Hosokawa supplies process solutions for the manufacture of different types of pigments for use in the production of paper.

Fig.1 1120 ANR for the production of fillers, pre and top coating pigments

Fig.2 Applications

GCC (wet)

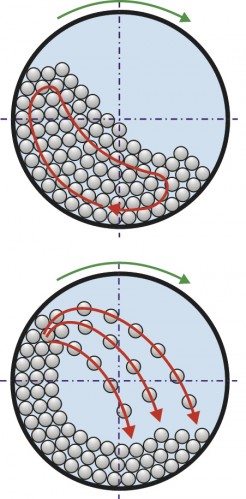

We employ the vertical agitated ball mill ANR for the wet grinding of GCC.

PCC as an alternative to GCC

Precipitated calcium carbonate (PCC) is a synthetic product produced by means of a chemical precipitation process.

Features

- High reliability

- Low energy consumption

- Steep particle size distribution

- Low rotor speed

- Long rotor life thanks to ceramic wear protection

- Contamination-free end-product

- Large cooling surface

- Low and high solids concentration possible

Drying calcium carbonate

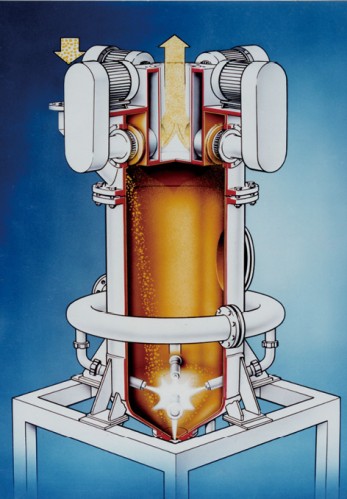

Fig.3 Drymeister DMR-1H

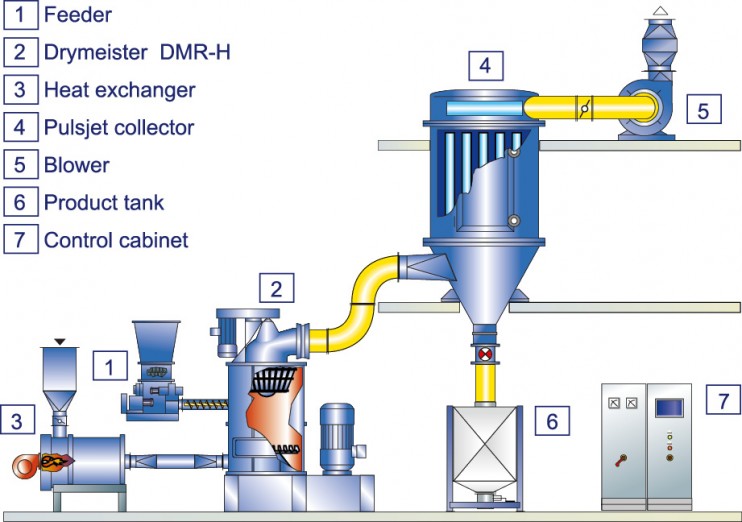

Most of the cases of wet milled GCC and PCC after filtration, post drying is necessary. Hosokawa Drymeister (DMR-H) is the most recommended dryer for this application. Setting the high inlet air temperature, a very economical and effective drying condition is presented to calcium carbonate producers.

Drymeister provides three functions in one machine; grinding, drying and classifying. Thus, no further grinding is necessary.

Fig.4 Flow of Drymeister

Kaolin and gypsum

Fig.5 Wet agitated ball mill 315AHM

Kaolin and gypsum are ground with the agitated ball mill AHM.

When grinding gypsum, additional know-how with respect to the additives used is necessary if the desired specifications are to be met. For coating operations, ground gypsum instead of kaolin can be used. Thanks to the low density, a thicker coating at constant weight (g/m2) is achieved with gypsum, or at the same layer thickness, the weight of the paper can be reduced and the gloss increased.

Talc

Fig.6 Schematic figure of AFG

Fluidized bed opposed jet mills AFG are used for grinding talc, and provides excellent delamination and ensures the sharp top-size limitation demanded by the paper industry.

Related equipments

Feel free to contact us. if you have any questions or concerns.