- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Rice Powder

Rice Powder

Summary

Rice powder is milled powder of ordinary rice or sweet rice. There are various types of rice products, and are used for rice cake, dumpling and Japanese confectionery, the same as wheat flour. It is also used for noodles and bread it plays a role of alternatives to wheat flour for allergy purposes. There are two types: non-heat treated Beta type (raw rice product) and heat-treated Alfa type (gelatinized product). Beta type of ordinary rice is used for rice powder bread.

Contents

Demand from industry

For the production of rice powder, there are 3 milling types: roller mill, stamp mill and impact mill. There are proper processes for each product of High and White Powder, High Powder, and wheat flour replacer. For each final product such as rice cakes or dumplings, the product quality is affected by particle size, shape, and moisture content of rice powder. In order to protect starch fraction from damage during milling, it is very important to dip rice into water to let it absorb moisture prior to the milling process. This treatment suppresses the temperature rise of product. For the wheat flour replacer, finer product (around 40 μm) than conventional rice product (around 100 μm) is required. It tends to increase the demand for impact mill.

High and White powder (Roller mill)

water absorption – drying

milling – sieving

High powder (Stamp mill)

water absorption – dewatering – milling – sieving – fluid bed drying

Wheat flour replacer (Impact mill)

water absorption – dewatering – milling

drying

Fig.1 Dipped rice

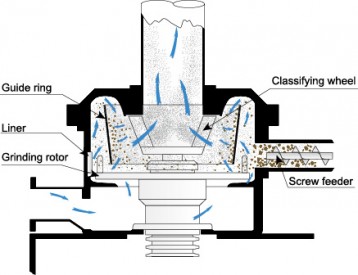

Fig.2 Schematic figure of ACM Pulverizer

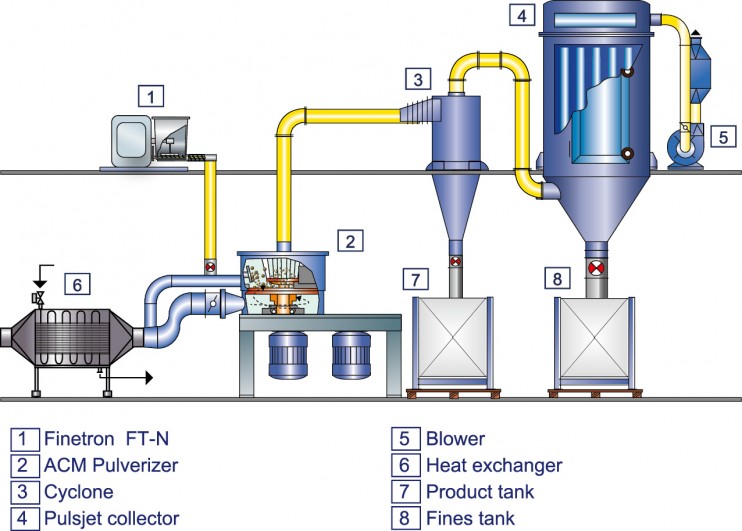

Fig.3 ACM Pulverizer ACM-10A

Problem

Roller mill is suitable for mass production, but requires the use of a sieve for particle size control. Stamp mill can be operated in low temperature to minimize, but system for particle size is difficult to control. The system of impact milling is compact and easy to control the particle size. Another advantage of impact milling could be the combination with drying operation in one machine.

Modern milling system

For fine grinding of rice, our recommendation is ACM pulverizer. Compare to multiple roller mill, structure of milling rotor of ACM is simpler and easier to clean up. It can be scaled up to more than the production capacity 1t/h. It has advantage on scale merit (low energy consumption) for large system compare to multiple rotor type milling. In addition, it grinds the rice with little damage to starch because of milling at minimum necessary impact. By blowing hot air directly to mill, milling and drying process can be conducted at the same time. Simple and smooth interior structure enables continuous processing without adhesion and results with improved productivity by laborsaving on cleaning. It also suppresses the bacteria breeding in the system. As the high performance-classifying rotor gives steep particle size distribution curve, the product can be applied for the high quality product such as bread or confectionery.

Fig.4 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.