- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Instant coffee

Instant coffee

Summary

The market valuation of instant coffee has been changing. A good aroma like dripped coffee is liked. In order to produce these instant coffees, it is important to develop new manufacturing methods.

Contents

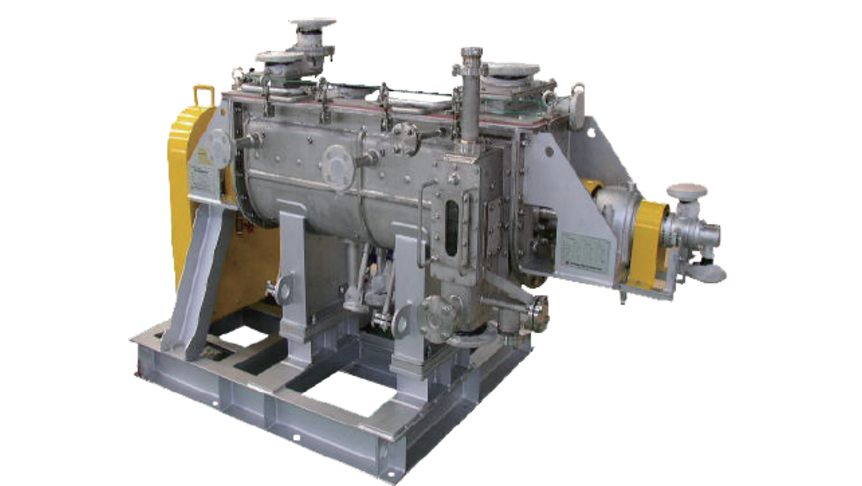

Fig. 1 Low temperature grinding system

In order to produce more valuable instant coffee, it is important to give more aroma and good taste. One method to satisfy the request is to mill the fine particles of coffee beans and add it to the instant coffee

However, the general milling method is very difficult because the heat generated during milling affects the aroma and taste. We recommend customers to utilize the low temperature grinding method, the HOSOKAWA/MICRON Linrex Mill.

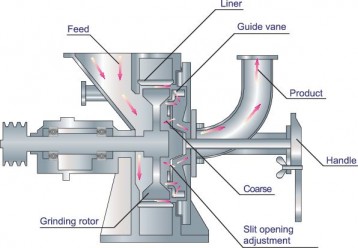

Fig. 2 Structure of Linrex Mill

It can grind such materials effectively while preventing degeneration of the material from the heat generated during grinding or oxidization. This system can realize very economical grinding of coffee beans because of the structure.

Linrex Mill has an internal classifier and utilizes an impact grinding method to grind the materials effectively.

Moreover, it has an innovative energy saving design where the freezer and cyclone are stored in a compact cold insulation box to minimize cool temperature loss.

Fig. 3 TorusDisc

The ground coffee bean will be moist due to dewing when it is returned to room temperature. We propose to use the HOSOKAWA/BEPEX TorusDisc which is continuous indirect dryer to dry the moisture of cryogenic ground products.

By adding the ground and dried coffee powder to conventional instant coffee, you can make the aromatic and deep flavor coffee.

The following is an example of typical performance (milling of roasted coffee beans).

Capacity : 170 kg/h, Product d50 : 20 µm

Related equipments

Feel free to contact us. if you have any questions or concerns.