- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Rubber Chopper PB

Rubber Chopper PB

Summary

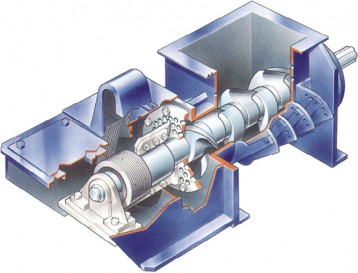

The Rubber Chopper is a coarse grinding machine that comes equipped with an anvil, hammer, orifice plate, and cut-off knife. It uses shearing and crushing forces generated by the slowly rotating rotor for size reduction. The Rubber Chopper has a very durable structure for its purpose and operating condition. Natural Rubber, Synthetic Rubber, and Regenerated Rubber used as a principal raw material for plastic, resin, and rubber products such as tires, are usually transported in large blocks (called “bale” with an approximate size of 400 x 200 x 800mm and weight of 35kg). However when a mixing process with other various materials and/or solutions is involved, a primary grinding operation is required to quicken the mixing process. The Rubber Chopper is the ideal machine for this primary grinding operation.

Principle

Grinding Mechanism

Fig.1 Schematic figure of PB

A Screw type main hammer that rotates at a low speed of 10-40rpm is located at the bottom of the raw material hopper. This rotor moves and pushes the material being processed against the orifice plate installed at the product outlet side, while applying shearing force generated in-between the anvil and adjustable anvil in the process. The hammer and cut-off knife are each equipped with separate motors. The orifice plate has a 2-piece design, which allows it to be removed without having to disassemble the shaft. The amount of raw material being taken in by the rotor can be adjusted by changing the position of the anvil.

Adjustment of the Product Size

- Orifice Plate / Aperture : Maximum Φ35mm (Round Hole Type)

*Round Hole is the widely used standard type. Other shapes such as the spoke type can be offered as well. It has a 2-piece design for easy removal. - Cut-off Knife / Rotor Speed : Has an operation capacity of 200-1,000rpm.

Process Capacity

Since the hammer is designed in a screw-like manner, the process capacity is substantially proportionate to the rotor speed. The motor horse power required to achieve the target process capacity can be calculated from the rotor speed, process capacity, and power generated from 1 rotation of the rotor retrieved from a test operation.

- PB-15 (SD) Model : max. 1.5kW/rpm

- PB-15 (HD) Model : max. 3.0kW/rpm

- PB-24 Model : max. 6.0kW/rpm

The process capacity largely depends on the bail type, viscosity, and solidity of the raw material but is generally 1.2 - 6 tons/h.

Features

- Has a durable design and can generate a very large torque.

- Has a low abrasion and noise level due to operation at low rotation speeds.

- Has a low required power level.

- The temperature increase of the product is low, with minimal affect to the product quality.

- Easy Maintenance

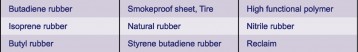

Table 1 Applications

Options

Fig.3 Rubber Chopper with automatic feeder

Ram Feeder

Generally one bale has a weight of approximately 35kg, making it difficult to feed the raw material manually. Also, depending on the elasticity of the raw material, there were times when coarse particles would shoot out of the inlet leading to a decrease in operating efficiency. With the development of a pneumatic type ram feeder, (Bale Feeder) operating efficiency as well as hazardous work has been limited, leading to an increase of processing speed.

Feel free to contact us. if you have any questions or concerns.