- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Micron Thermo Processor MTD

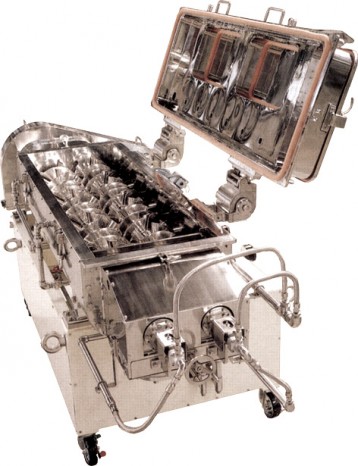

Micron Thermo Processor MTD

Summary

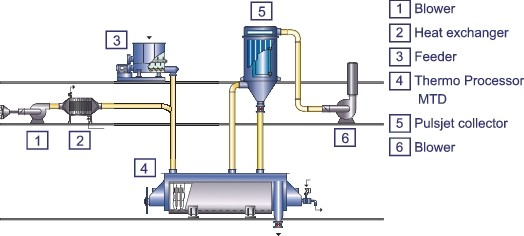

Micron Thermo Processor is an indirect heating type twin shafts disc dryer with jacketed trough casing. Twin shaft construction gives large heat exchange area and self cleaning effect showing the appearance in Fig. The series gives three types; M type, C type and F type. M type has 2 fan-shaped hollow heat transferring wings for high mixing ability. This type is applicable for poor flowability material, such as sludge and the advantage is high capacity drying for constant rate period. F type has dual torus discs with jacketed trough and the improved plug flow characteristics is expected. It is applicable for drying good flowability material for the drying period of the decreasing rate of drying. C type has the advantage of both M type and F type. It has high plug flow, less adhesion and wide application. It is useful for constant rate period to decreasing rate of drying. It can be applied to various applications from sludge to food and pharmaceutical.

Principle

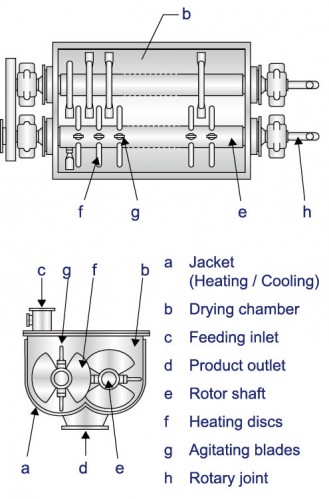

Fig.1 Schematic structure

MTD consists of a horizontal W shaped trough with heating jacket and dual rotor with multiple discs. Material is continuously agitated, heated and conveyed, then discharged via adjustable overflow weir. Heat medium, such as steam, hot water or thermal oil flows via rotary joint through the hollow rotating shaft and the heat transfer discs. Compact unit with large transfer area realizes effective drying. Dual shaft structure makes scraping effect to the material around the disc, to prevent the material from adhering on the discs. Control of moisture content is carried out by adjusting weir height or rotating speed of rotor. MTD F type and TorusDisc can apply oil as a heat medium.

Features

- Wide application for different rotor shape

- F type has higher plug flow, and suitable to low moisture material

M type has higher mixing ability, and suitable to sludge like material - Efficient heat transfer

Unique design of drainage mechanism inside the disc gives large heat transfer coefficient. - Little adhesion by dual rotor construction

Smaller adhesion by scraping effect around disc. Scraping effect can be controlled by rotating speed or rotating direction. - Compact unit with large heat transfer area

- Larger heat transfer capacity and heat transfer coefficient

- Drying time control by weir height

With adjustment of the agitating blade angle or weir height, residence time of the material can be controlled. - Stable quality of product

C and F type give higher plug flow and less short pass. Uniform drying and stable product can be obtained.

Fig.2 Flow

Applications

Suitable for drying food additive, SAP, wheat flour, synthetic resin, detergent, surfactant, pharmaceutical, organic/inorganic chemical and sludge.

Feel free to contact us. if you have any questions or concerns.