- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

E-PVC

Summary

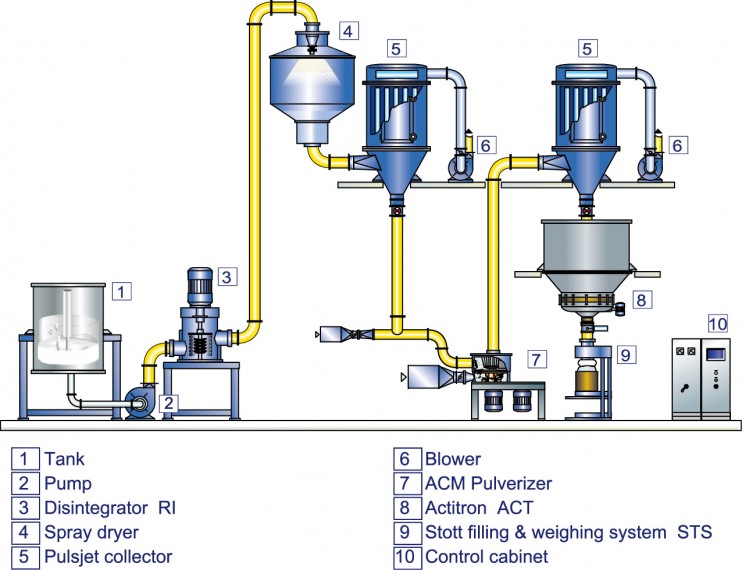

Complete grinding-classifying systems for E-PVC

E-PVC precipitates as a powder subsequent to a spray-drying process. The most important applications are plastic film, profiles, floor coverings, wall paneling, coated materials, sealing compounds and plastisols.

E-PVC is generally required with fineness of < 63 µm and < 40 µm or even finer with a steep top cut. And because these requirements cannot be met by spray dryer alone, grinding and classifying technology is always necessary.

The grinding-classifying process is performed with ACM Pulverizer. The classifier is integrated in the top section of the mill to perform the clean top cut. ACM Pulverizer is the most appropriate for this application because the mill is designed optimum accessibility, easy cleaning and cool grinding.

Contents

ACM Pulverizer for E-PVC

ACM Pulverizers have been delivered world-wide for the fine grinding of E-PVC these days. A series of models are provided to meet various capacity requirements; ACM-15 to ACM-300

Features

- High grinding performance at good product quality

- Adjustable parameters such as mill speed and classifier speed

- Simple to operate and quick to clean

- High mechanical reliability

Options

- Temperature monitoring of classifier and mill bearing, etc.

- Permanent monitoring of the bearing for vibrations

Hosokawa has delivered the largest model ACM-300 (220kW) for this application.

The chemically synthesized paste resin contains agglomerates which have to be dispersed before spray drying. In order to break the agglomerates, the Disintegrator RI is installed in prior to the drying process.

Fig.1 Mock-up of Disintegrator

Fig.2 Disintegrator

Fig.3 ACM Pulverizer ACM-300

Fig.4 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.