- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Pigments and Dyestuffs

Pigments and Dyestuffs

Summary

Pigments are insoluble substance in water or alcohol. They are used as ingredients in paint, ink, cosmetics, etc. as coloring substances. Pigments are classified into 2 types: organic and inorganic pigments. Inorganic pigments can be divided into 2 types: natural mineral pigment and synthetic inorganic pigments. Dyestuffs are dissolved in a solvent and used for coloring fiber, paper and others.

Contents

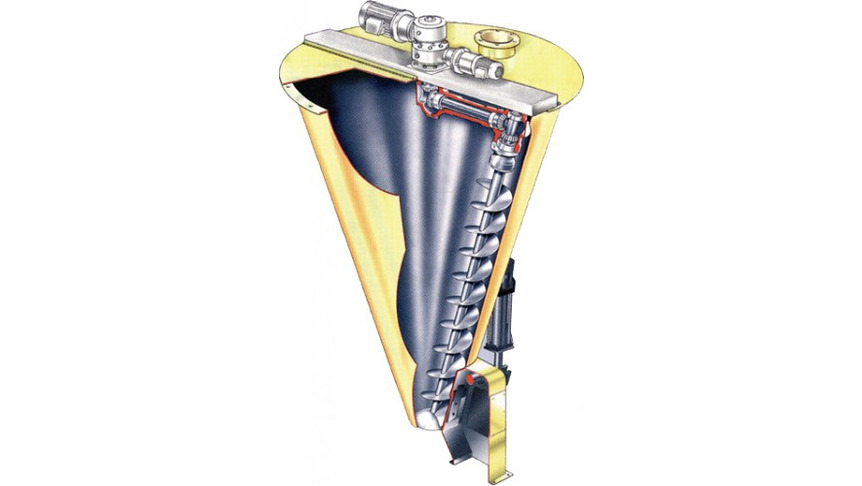

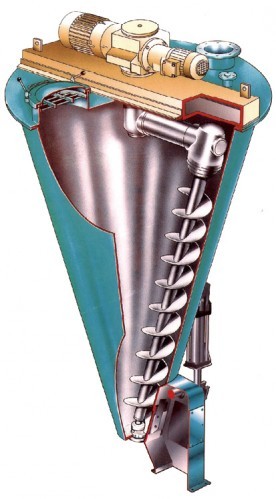

Fig.1 Vrieco Nauta mixer

The dry grinding and classifying of pigments and dyestuffs must pay attention to the extremely critical product properties. These products have a high tendency to form deposits, which increases the risk of system blockages. Because of this, it is impossible to give a generally valid rule regarding machine selection with fineness or throughput values. Each machine and every system must fulfill a great number of requirements. We therefore modifies its systems to suit the product: special mills with wide-chamber housings; modified fluidized bed opposed jet mills; fluidization units for locations where deposits are likely to form; installation of flexible rubber linings; hot-air mode; the addition of grinding aids, etc.

Also, in the mixing process, various sizes of Vrieco Nauta Mixer (Fig.) are adopted for higher accurate performance and time- and energy-saving operation.

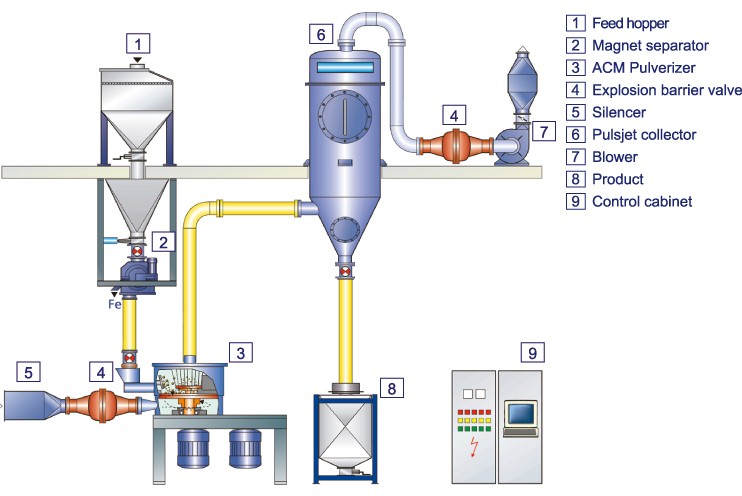

System

Various option of grinding machines is possible depending on the figure and target particle size of powders.

- Contraplex pin mills CW

- ACM Pulverizer

- Fine impact mills UPZ

- Fluidized bed opposed jet mills AFG

Classifier ATP and TTD are suitable for separation of contaminants and oversize particles.

Fig.2 Flow

Contraplex pin mills CW

Fig.3 Contraplex 250CW

Contraplex mills are versatile in operation in the paint industry. Special features are the wide-chamber housing to prevent formation of deposits, as well as high grinding fineness and low energy consumption.

Fine impact mills UPZ

The many different equipment variants of these wear-insensitive systems make optimum adaptation to any feed product possible.

ACM Pulverizer

Fig.4 ACM Pulverizer ACM-10A

High-tech systems for end products with steep particle size distributions and exact top-size limitation.

Fluidized bed opposed jet mills AFG

Fig.5 Fluidized bed opposed jet mill 400/1 AFG

Fluidized bed opposed jet mills are suitable for abrasive ceramics pigments since it is advantageous on wear protection and reduction of build-up products.

Drymeister DMR, DMR-H

Fig.6 Drymeister DMR-1H

Drymeister is the most suitable for drying organic pigment such as blue, green, red, etc.

Related equipments

Feel free to contact us. if you have any questions or concerns.