- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

Milling

Summary

Milling is an important part of pharmaceutical production. The major uses and purposes of milling for pharmaceutical production are shown below:

Milling process for active substances

- Equalize active pharmaceutical ingredient (API) particle size

Fine Impact Mill UPZ (Left figure)

- Increase solubility by fine milling

Fluidized Bed Opposed Jet Mill AFG (Fig.1)Milling process for drug formulations

- Milling of excipient to adjust the particle size prior to mixing allowing for uniform content

Fine Impact Mill UPZ

- Milling and mixing of excipient and pigment

Fine Impact Mill UPZ

- Particle size adjustment of agglomerates

Pharma Mill FM-P

- Milling of API

Spiral Jet Mill AS (Fig.2)

Milling process for pharmaceutical development

- Milling of several grams of developmental materials

Desk-top Machine Picoline

Contents

Fig.1 Fluidized bed opposed jet mill 200AFG in pharma design

Fig.2 Spiral jet mill 100AS in pharma design

Milling of pharmaceutical ingredients, Fine Impact Mill

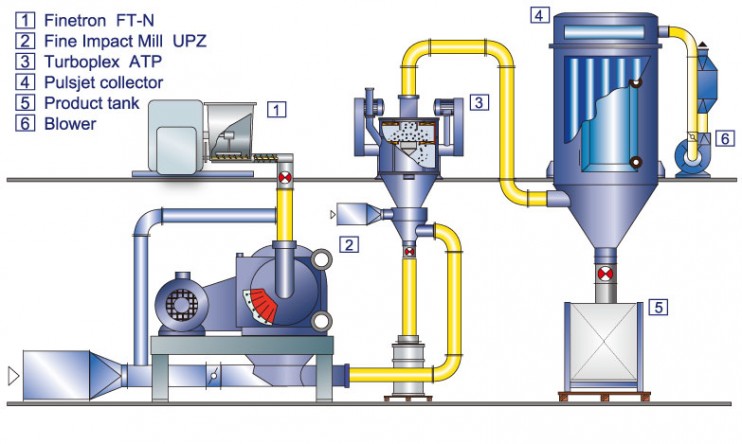

For APIs and excipients, materials of several mm size is milled to 10 μm particle size using impact mills is common. The Fine Impact Mill UPZ can easily control the particle size of the milled product and is also easy to disassemble and clean. The standard system consists of a feeder - mill - product collector. Systems operating with cooled air or inert gas have been delivered and sizes from laboratory to production capacities are in use by many pharmaceutical companies.

Fig.3 Flow of UPZ

Jet Mill Integrated into an Isolator System

Fig.4 Mill integrated in isolator

For poor solubility drugs, increasing bioavailability by milling to particle sizes of several microns increases the specific surface area, which in turn increases the dissolving speed of the drug. Jet mills are commonly used for this application.

There are two types of Jet mill, Spiral Jet Mill AS and Fluidized Bed Opposed Jet Mill AFG. With the Fluidized Bed Opposed Jet Mill AFG, controlling the product particle size can be easily achieved by adjusting the classifier speed, making quality control simple. There is very little buildup of material and wear making the jet mill suitable to process pharmaceutical ingredients which tend to be very adhesive powders. Milling of API increases the specific surface area and surface energy resulting in an increased potential for dust explosions. Preventive measures such as using inert gas for the milling gas are generally used.

For milling of pharmaceutical ingredients using the Spiral Jet Mill AS or Fluidized Bed Opposed Jet Mill AFG, milling in inert gas in a closed loop circuit or installation in an isolator with an inert gas atmosphere is possible.

Related equipments

Feel free to contact us. if you have any questions or concerns.