- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Spices, Herbs and Dried Vegetables

Spices, Herbs and Dried Vegetables

Summary

Grinding spices is one of most challenging comminution tasks of all. Not only does the structure of spices vary widely, but also the grindability. Some spices - for example turmeric - can differ dependent on how they are grown and when they are harvested.

Hosokawa delivers complete systems for any spice and dried vegetable for every fineness requirement and final application, whether it is for sauces, soups, curd cheese, cheese, sausage, spice blends or bakery products. Dependent on the specification, we offer systems for the following process steps: cleaning, crushing, cutting, fine grinding, cryogenic grinding with CO2, LN2, sieving, sorting, mixing and packing, etc. tailored to the individual products or in the form of a multi-processing system.

As a function of the products - the properties of which such as hardness, size, oil content, shearing resistance and toughness vary widely - we offer different systems tailored to the respective requirements for spices and dried vegetables:

- Cutting with the Rotoplex Ro

- Fine grinding with the Ultraplex UPZ

- Fine grinding with the Contraplex CW

- Cryogenic grinding with the UPZ, CW or LX

Contents

Cutting with the Rotoplex Ro

Fig.1 Rotoplex 28/40 Ro

Spices and herbs, etc. are finely cut with a minimum of dust using Rotoplex granulators. Typical applications are ginger, chestnuts, garlic, and oregano, fresh and dried plants.

Fine grinding with the Ultraplex UPZ mills

Fig.2 Fine impact mill UPZ(Plate beater)

These mills are equipped with interchangeable grinding elements, thus giving the user a maximum degree of flexibility, something that besides the actual grinding performance is becoming more and more important these days. The UPZ is widespread in the international spice industry as a universal all-round mill for granular to ultrafine end products. It is suitable for just about every type of spice except for those with an extremely high content of oil.

Ultraplex fine impact mills UPZ

The material properties, and especially the wear behavior, dictate selection of the mill. UPZ mills are the mill of choice for root spices, seeds, fruit skins and husks with high ash content and extremely hard kernels such as rose hips.

Fine grinding with the Contraplex CW

Fig.3 Contraplex 800CW

Thanks to their universality, especially in the case of extremely greasy and heat-sensitive spices for which other systems are totally unsuitable, Contraplex mills are considered the classic spice mills. Even with spices that are extremely critical in terms of grinding, Contraplex mills are perfect for continuous operation over prolonged periods.

Contraplex pin mills CW

Speed and rotational direction of the two pin discs can be selected such that in spite of high end-product fineness values, the grinding process is gentle to the product with optimum retention of the essential oils.

It is only possible to quote reference values here because of the enormous differences in the grindability of the different spices. A number of factors influence the grindability, e.g. moisture, purity, the content of essential oils and the origin of the spices.

Contraplex wide-chamber mills CW

The heat generated when grinding spices leads on the one hand to volatilization of the essential oils, and on the other hand causes the heat-sensitive fats to melt. In the worst case, this can cause the grinding elements to clog up or the entire mill to block and stall. Because of this and to optimize the product properties and process control, cryogenic grinding is used for these types of products.

Cryogenic grinding

Generally speaking, CO2 or LN2 are used as the cooling agents.

The product and system are cooled either by direct injection of the cooling agent into the mill or, if longer residence times or lower temperatures are necessary, by precooling and embrittlement of the material in a screw cooler.

Enthalpy CO2 330 kJ/kg (-20°C)

Enthalpy LN2 363 kJ/kg (-20°C)

Because cryogenic grinding reduces the loss of essential oils (approx. 3 - 10% loss) in comparison with grinding at ambient temperature (approx. 15 - 43% loss), it is possible to improve the aroma and flavor. In addition, the grinding performance is about twice as high and the risk of fire is eliminated.

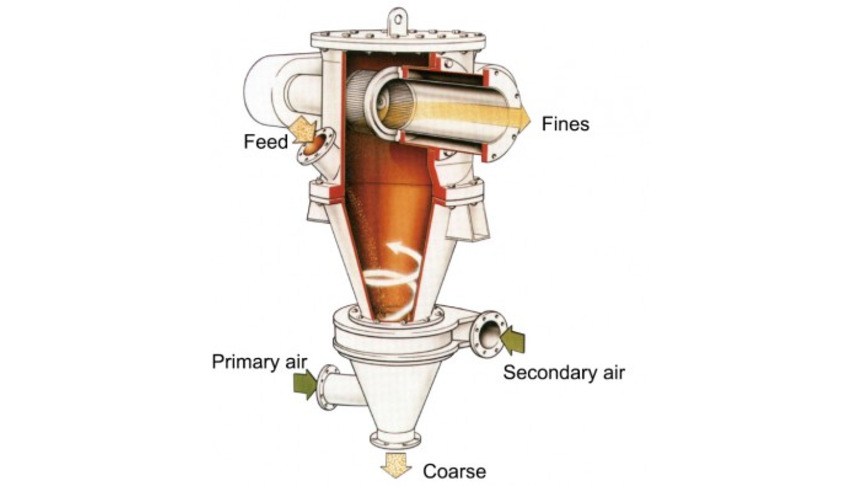

For extreme fine grinding requirement, Hosokawa Linrex mill LX is recommended. Linrex mill is the static classifier integrated impact mill working in cryogenic condition.

Fig.4 Cryogenic grinding system by Linrex mill

Related equipments

Feel free to contact us. if you have any questions or concerns.