- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- ODTs (Orally Disintegrating Tablets)

ODTs (Orally Disintegrating Tablets)

Summary

ODTs (orally disintegrating tablets) are tablets that can be taken without water. It is convenient in the case there is no water and/or when the recipient does not want others to show about taking medicines, so nowadays the commercialization proceeds. However, ODTs require different quality and formulation from conventional tablets because it has to dissolve in the mouth.

Contents

Fig.1 Tablets

Generally tablet is composed of the following materials.

APIs: It is an active ingredient included in the pharmaceutical production.

Excipients: Generally API is not easy to handle due to the very little volume. Excipients are used for protection of API from moisture, UV, etc. because the API is made easy to handle or foam tablets. (Lactose, Crystalline cellulose, Starch, etc.)

Binder: It is used as glue when it is difficult to firm without binder. (Cellulose derivative, etc.)

Disintegrates: It helps to release active ingredients by disintegrating tablets with moisture from oral cavity (or gastroenterology). (Starch, Cellulose, Carbonate, Cross povidone, etc.)

Lubricants: It improves the flowability of powder and helps to fill for forming tablets and compress molding. (Magnesium stearate, Talc, Hydrogenated vegetable oil, etc.)

Coating materials: It is used to protect tablets from moisture, light, etc., eliminate the bitter taste, and let medicines solve in not stomach but intestine. (Sucrose, Wax, Polymer, etc.)

ODTs need the following properties in addition to the above,

Property1. Fast disintegrating: It becomes fine particles rapidly to naturally swallow.

Property2. High strength: It is unbreakable during transportation and handling. The strength is important because it is often carried.

Property3. Administering property (taste and food texture): It can prevent from feeling food texture (roughness) and taste (bitter taste) easily due to disintegrate medicine in the mouth and disperse APIs around the tongue.

Fig.2 Absorbed and swelled ODT

Property1 is an essential requirement as ODTs. It’s important that the pressure to foam tablets, physical/chemical properties and combination of API, disintegrates, binder, etc.

Property2 is generally required for tablets. It is difficult to disintegrate in the mouth if the strength is pursued. The formulation is important to add the suitable strength.

Both Property1 and Property2 are largely influenced in the kinds of chemical substance and change even if they are the same chemical substance depends on powder characteristics – particle size and morphology. Therefore, the control and evaluation of powder characteristics play a more important role than making conventional tablets.

Property3 cannot solve by the conventional methods of whole coating of tablets, so the development of new process is required.

Ultra fine grinding associated with fast disintegrating and strength (The above Property1 & 2)

The hardness of tablets and disintegrating time change depends on the particle size of disintegrates and binder. For instance, T. Yokozawa and N. Maruyama reported that the hardness of tablets is high if composed particles are under 20µm when the powders of Methyl cellulose are used as binder by dry direct compression method. In addition, the smaller (minimum 4.3µm) particle size gives, the better fast disintegrating performances.

On the other hand, if Mannitol and so on is ultra-fine ground, the flowability is getting worse and they are not suitable for formulation. These various knowledge are applied to improve the quality of ODTs.

Conventionally, fine grinding (dozens of µm) of pharmaceutical materials was often used Fine impact mill UPZ that can use grinding parts in a plate of pin or grinding disc and ultra-fine grinding (a few µm) of them was often used Spiral jet mill AS. In the case that customers need products has narrower particle size distribution than ground products by AS, Fluidized bed opposed jet mill AFG with a built-in classifier has been used.

Fig.3 Fine Impact Mill UPZ

Fig.4 Spiral Jet Mill AS

Fig.5 Fluidized Bed Opposed Jet Mill AFG

Fig.6 Impact Jet Mill MJQ

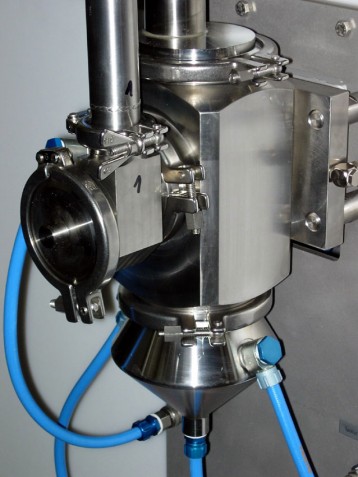

However, ODTs requires finer particles than conventional ones, so ultra-fine grinding machine integrated with high classifying ability and grinding efficiency, Impact Jet Mill, Micron Jet type Q is attracted attentions. This equipment can grind some kind of polysaccharides used as binder and wax used as coating agent more finely with higher capacity than Spiral Jet Mill and Fluidized Bed Opposed Jet Mill.

Ultra-fine grinding and dry particle composing technology to improve administering property (the above Property3)

ODTs have a long time to stay near by tongue compared with taking general tablets, therefore it takes long time for the recipients to feel bitter of drug and causes some problems of administering property. That is why the coating solution is required to mask the bitter taste for APIs and mixture API and excipient.

However, there is a problem. The recipients feel the roughness in the mouth during dissolving if the particle size is large because APIs are not easy to dissolve tend to increase. It is necessary to make particle size as small as possible in order to prevent from these problems.

Coating of APIs is difficult due to miniaturization. Fluidized bed coating is widely used as coating technology of pharmaceutical particles, but it is difficult to fluidize ultra-fine particles then coat by spraying of coating liquid.

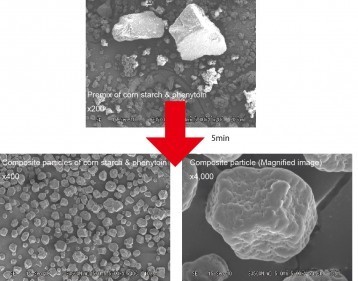

Dry composing machines that can coat much smaller particles with fine particles (Nobilta NOB and Mechano Fusion AMS) are attended attentions. These machines can coat powdered binder with fine particles of APIs.

Fig.7 Table type Nobilta NOB

Fig.8 Nobilta (high cooling type) NOB

Fig.9 Mechano Fusion AMS

Fig.10 Example of particle composition (cornstarch coated by phenytoin)

These equipment have the following features.

- no residual solvent

- unnecessary for drying process = low running cost

- short processing time

Therefore, various study reports are known. For instance, the study that coated additives on the surface of APIs and evaluated tabletability and dissolution characteristic is reported by M. Hujinaga, Y. Yoshihashi, E. Yonemochi, and K. Terada, Journal of the Society of Powder Technology, vol.48, pp.618-624 (2011).

The study that surface enhanced lactose particles as DPI career is reported by M. Kumon, M. Suzuki, E. Yonemochi and K. Terada, Chem. Pharm. Bull. and Q. Zhou, L. Qu, I. Larson, P. J. Stewart, D. A. V. Morton, J. Powder Technology, vol. 207, 1-3, pp. 414-421 (2011).

Moreover, these days there were the reports that Nobilta can make the spherical granulators simultaneously with grinding. (For example, “The 31st proceedings of Annual meeting of the academy of Pharmaceutical Science and Technology” reported by T. Niwa and K.Kondo, Round table 2 “Spherical grinding method: hybridization of dry grinding and sherardizing”, 61 (2016) reported by T. Niwa, and Intl. J. Pharmaceutics, vol.483, pp.101-109(2015) reported by K. Kondo, A. Kato and T. Niwa, Intl. J. Pharmaceutics, vol.453, pp.523-532(2013) reported by K. Kondo, N. Ito, T. Niwa and K. Danjo reported.)

Nobilta can dry coat as a nucleus of particle obtained by this way. (“The 31st proceedings of Annual meeting of the academy of Pharmaceutical Science and Technology”, pp.140 reported by T. Niwa, K.Kondo and A. Kato)

These technologies are considered that they can produce particles with properties of suitable for ODTs.

Powder measuring technology associated with fast disintegrating and strength (the above Property1 & 2)

As above, the particles that is material of ODTs are required properties differ from material particles had been used for conventional tablets. Therefore, they may cause troubles during mixing (coated) APIs particles and disintegrates or binder etc., filling to the tableting machine after mixing, and tableting. In order to solve these troubles, it is necessary to choose and operate the mixing method of appropriate lubricants or control particle size of each material. However, testing these enormous formulations by actual equipment is unreality.

The adjusting way of powder characteristics is known for feed materials of ODTs or mixtures/agglomerated powders by obtaining powder characteristics that have no problems in the conventional process. The difference of various values associated with the flowability or floodability among powder characteristics often cause troubles. Accordingly, it is important to measure Carr’s flowability or floodability index calculated by angle of repose, bulk densities (aerated and tapped), angle of fall, angle of spatula, and these figures.

Fig.11 Powder Characteristics Tester PT-X

Sometimes low cost jig is used to measure these characteristic values, however they cause big difference depends on operators. The value drastically changes depend on measurement conditions, so it is a necessary measuring instrument which can solve the defects.

Powder Characteristics Tester PT-X is used as equipment of defact standard in the world.

Powder Tester is applied to not only pharmaceuticals but also various powders and we publish the parts (300 kinds of powders) of measuring result on our website.

Fig.12 Air Jet Sieve e200LS

There is sieving equipment as other important measuring system. This is a method of important quality control described in Japanese, American and European Pharmacopoeia.

A vacuum suction type of dry sieving equipment, Air Jet Sieve is used in the world for verification testing of crystalline cellulose.

Fig.13 Viblette VBL-F

A wet type of sieving equipment, Viblette is used for analyzing of particle size of crospovidone (polyvinylpyrrolidone) attracted attention as disintegrates of ODTs.

The insolubility crospovidone is classified 2 types (type A and type B) from residual mass of powders on the sieve by Pharmacopoeia. This is written to use a wet sieving. (Please check the page of “US Pharmacopeial convention”).

However, it is difficult to sieve because the insolubility crospovidone swells by water.

Fig.14 Dispersion of sample by shower

The way to use general dry sieving equipment equipped with shower system is low cost, however spraying water uniformly is difficult and dispersion state of the powder is not good.

Moreover, water is not easy to pass the sieve because insolubility crospovidone swells by adding water, so operators have to carefully spray water not to overflow. They have to weaken the power of spraying, so the dispersion of sample is suppressed and it causes less efficient of sieving.

Fig.15 Peneto Analyzer

Our technology can evaluate not only powders but also tablets. Generally, the physical evaluation of tablets measure hardness, friability, dissolution characteristic, etc. In addition, the important factors are disintegrating situation in the oral cavity and speed of absorption of water related with it.

These days Peneto Analyzer PNT-N is spotlighting because it can offer the hints for the amount of disintegrating agents and tableting conditions from the penetration behavior of water measured by it. The 31st proceedings of Annual meeting of the academy of Pharmaceutical Science and Technology, “The designing of fast disintegrating tablets by water penetration method”, pp.235 (2016) reported by T. Takatori.

Fig.16 Colanta cell that can measure an ODT

Example of evaluation for absorption of water of ODTs by colanta cell

Feel free to contact us. if you have any questions or concerns.