- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Corporate Vision

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- FEATHER MILL FM, FM-P

FEATHER MILL FM, FM-P

Summary

The Feather Mill has the ability to grind raw materials as big as a few ten mm to roughly 0.2 - 3mm sized products by the impact and shearing force generated by the sharp knife hammers which rotate at high speeds. It is used for medium to fine grinding of many different types of materials such as chemical materials (resin, toner, powder coating, etc.), battery materials, foodstuffs, and magnetic materials. The Feather Mill is most suitable for grinding materials without the generation of fines. Since much of the grinding is done by the shearing force generated by the knife hammers, it is also often used for grinding of materials with low melting points.

There are two types of grinding rotor structures for the Feather Mill. The FM-S is a swing type feather mill where the knife hammers are attached to the rotor by pins. On the other hand, the FM-F is a Feather Mill with fixed knife hammers. There is also a model specifically designed for pharmaceutical applications that has a cantilever structure as well as fewer parts to make assembly and disassembly easy for cleaning purposes. (FM-1P, Fig.2)

("FEATHER MILL" is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

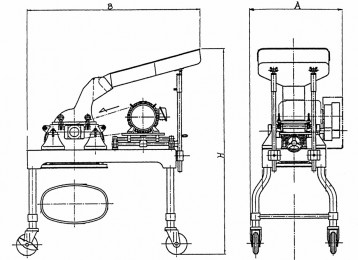

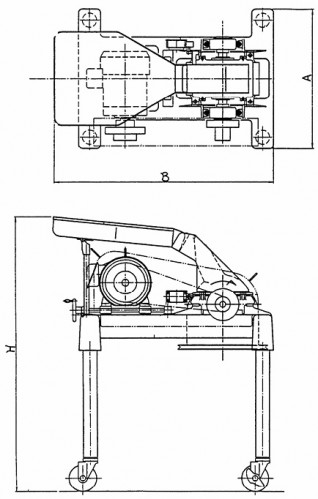

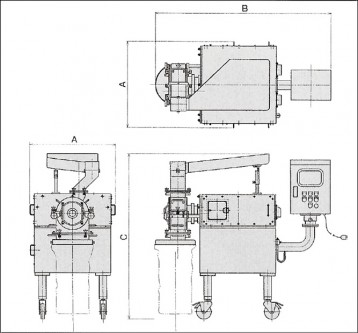

The main grinder, motor, and switch panel are all attached to a portable frame. (Fig. Feather Mill FM)

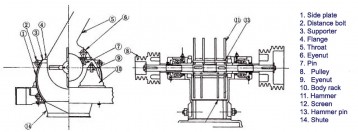

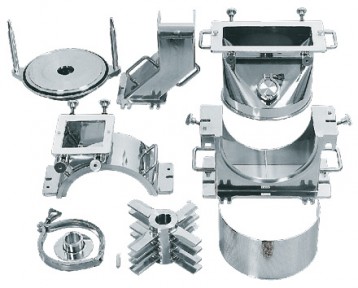

The interior structure is displayed in Fig.1. The rotor, as seen in the illustration, is installed in the inner portion of the upper and lower casings. The raw materials fed through the throat (5) are ground by the hammer (11) and materials that pass through the screen (12) are collected as products. An exhaust duct is attached to the chute (14) for dust emission and to prevent temperature rise. There are no liners in the grinding chamber making cleaning of the feather mill very easy as well as suitable for grinding moist materials. The FM-S has a structure where the bearing is integrated with the lower casing. The casing of the FM-F is merely for shaft seal purposes. By separating the shaft seal and bearing structures, the durability of the FM-F is increased. The FM-1P has a cantilever structure, allowing for easy disassembly of the rotor, casing, and grinding parts as shown in Fig.2 and Fig.3.

Fig.1 Structure of FM-S

Fig.2 FM-1P Disassembly

Fig.3 FM-1P Disassembled parts

Features

- The particle size can be easily adjusted by changing the hammer rotation speed as well as the screen size. The screen is simply installed into the screen rail and held in place by the throat, making it extremely easy to exchange.

- The simple grinding structure and short residence time reduce exposure of the materials to high temperatures. This makes the Feather Mill a suitable grinder for a wide variety of materials including heat sensitive materials.

- The pressure loss of the machine is very low, making it easy to incorporate the machine into any process line.

- The machine uses an eyebolt for installation and removal, making disassembly and cleaning very easy. The standard model is equipped with casters for easy mobility.

Applications

The Feather Mill is used mainly for disintegration of aggregates, filter cakes, and agglomerates, as well as grinding pharmaceuticals, foodstuffs, and materials with low melting points. A few examples are listed in Table 1.

Table 1 Applications

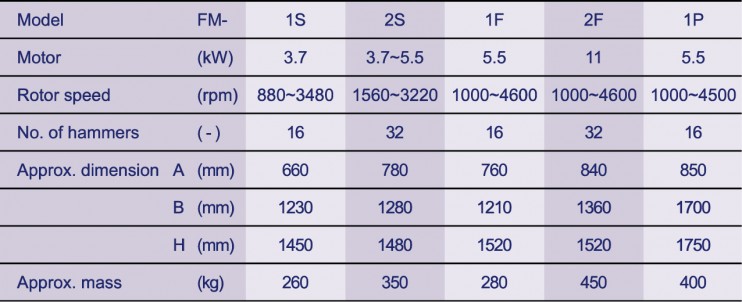

Specifications

Dimensional drawings of FM-S, FM-F, and FM-1P models are shown in Figs. 4, 5 and 6 respectively. The dimensions and specifications of each model are shown on Table 2. Larger scaled models are available. The largest type manufactured has a rotor size of Φ780 x 1000L with a power of 75kW for the application of detergent.

Fig.4 FM-S Type Dimensions

Fig.5 FM-F Type Dimensions

Fig.6 FM-1P Type Dimensions

Table 2 Specifications

Feel free to contact us. if you have any questions or concerns.