- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Management Philosophy

- Greetings (Company Introduction)

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Neodymium Magnet Material (Nd-Fe-B alloy), Metals

Neodymium Magnet Material (Nd-Fe-B alloy), Metals

Summary

Magnetic materials were typically made with hard or soft ferrite powder, but the use of rare earth metals as the base material is increasing. For high performance magnets(Neodymium magnet), Neodym-Iron-Boron (Nd-Fe-B) alloy milled by jet mills such as the Micron Jet-T MJT are used. Nd-Fe-B magnets are used for hard disc voice coil motors, high efficiency motors for automotive use, high performance generators for wind power generation, and energy saving motors for industrial air conditioners and vacuum cleaners. With increased efficiency and space savings, uses of high performance magnets are increasing.

Contents

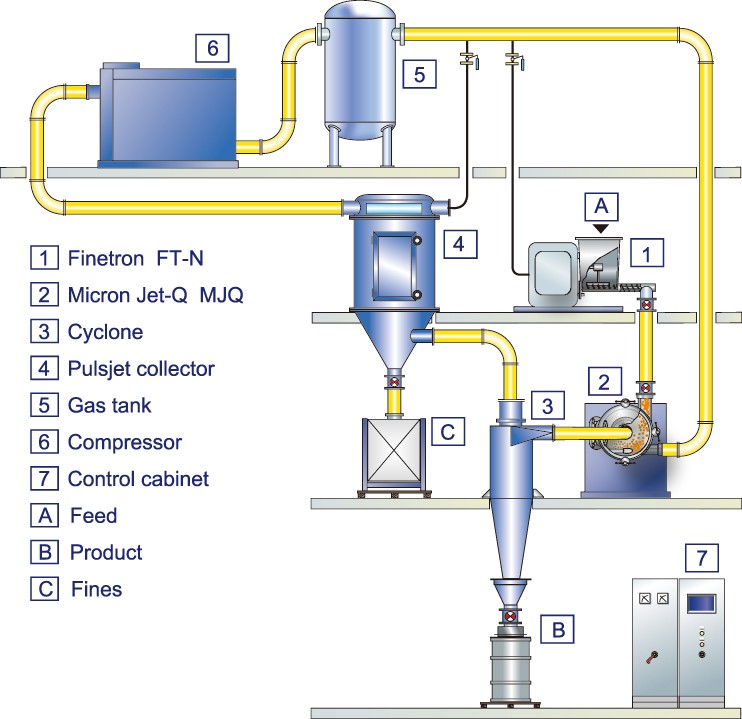

Inert Gas Closed Loop Milling System

Many of the alloys used for magnetic materials are pyrophoric and ignite when exposed to air. In the presence of even low concentrations of oxygen, the particle surface oxidizes. This make it necessary for production to be conducted within an inert gas atmosphere (for example, nitrogen or argon).

Hosokawa can supply specialized systems with an inert gas closed loop using inert gas compressors. Systems can have direct product collection in a bag filter or if there is frequent product changes, with a cyclone.

MJT

For the milling of Nd-Fe-B alloys, fluidized bed counter jet mills have been widely used. In order to meet market demand for finer particles, target type jet mill MJT is used.

The material holdup in the MJT is low so the same product can be produced during startup and shutdown.

- No Contamination or wear

- An integrated high performance classifier producing a sharp particle size distribution

- 50% less energy consumption compared to conventional jet mills

- Automatic and stable operation with inert gas

- Optional ceramic jet nozzle, target and classifier rotor

- Low material holdup

Fig.1 Flow of closed loop milling system (MJQ)

MJQ

Fig.2 Micron Jet-Q MJQ-1

The Micron Jet-Q MJQ was developed to process higher capacities than the MJT. Similar to the MJT, the MJQ is a target type jet mill with an integrated classifier that has a high-energy efficiency.

Online particle size analysis

Fig.3 Intellisizer XI

Intellisizer (Fig.3) is a particle size analyzer using the laser diffraction principle perfect for product quality control or process management. It can be installed online directly within a milling system enabling the safe measurement of material particle size without removing material out of the system. There is no loss of material due to sampling and particle size can be monitored continuously in real time on the PC display.

Related equipments

Feel free to contact us. if you have any questions or concerns.