- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Annual Publication "Micromeritics"

- Industrial Property Rights

- Journals and Books

- Technical Information

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

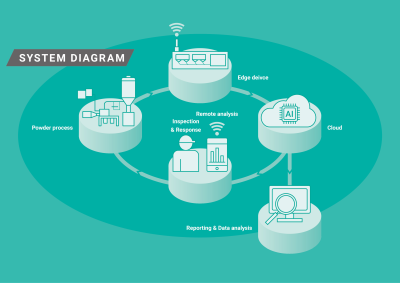

IIoT

GEN4 RM Assits to Start IIoT

HOSOKAWA GEN4 RM is one of the services in GEN4 series. HOSOKAWA GEN4 RM is a system that realizes Remote Monitoring.

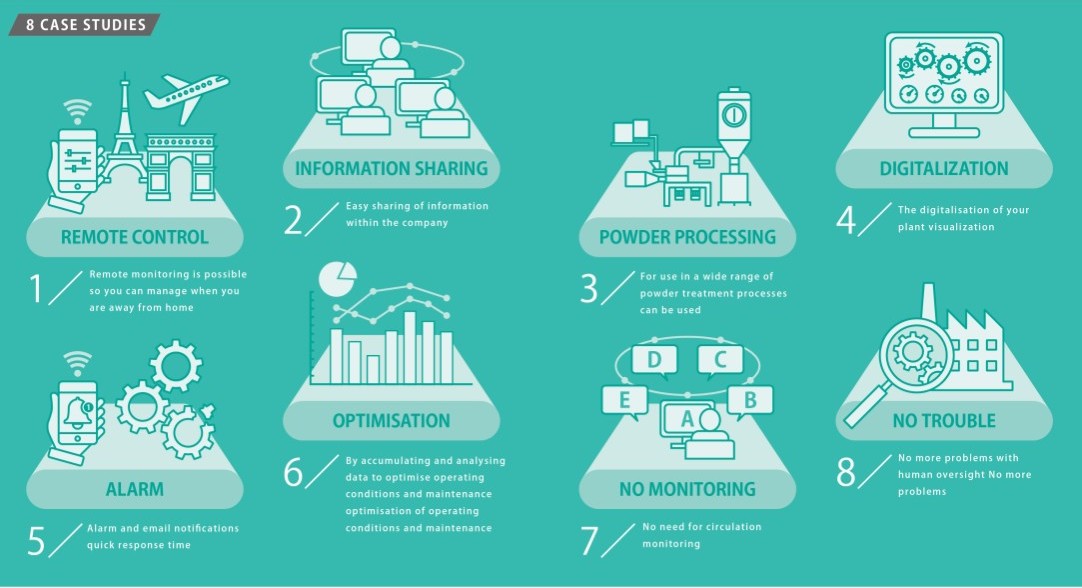

- Realize real-time quality and facility management.

- Equipment operation data can be accumulated and utilized as management resources.

- It can be used as a gateway to digitalization.

IoT SYSTEM

IoT system provides an environment to focus on data utilization.

Vibration conditions and temperatures can be monitored and recorded by the customer. The customer can monitor and record vibration conditions and temperature, and know what is happening in the process.

When a problem arises, you can look up past data to help solve the problem.

At the time of line expansion, the data can be shared with all concerned parties for quantitative study, which can be useful for better design/operation.

You can monitor the production status of remote locations at once from the office or on the road.

Main Functions

Remote monitoring

- Equipment operation data can be checked in the cloud.

- Equipment operation data can be stored in batches.

- Freely set alarms and receive notifications by e-mail.

- Monthly comparisons of operation status and detection of abnormal values are made easy, and labor savings can be expected.

Specifications of HOSOKAWA GEN4 RM

| Item | Spec. |

|---|---|

| Basic functions | Remote monitoring of operation data |

| CSV download of operation data | |

| E-mail notification of alarms | |

| What is included in the basic service | Gateway main unit |

| Connecting the control panel to the gateway | |

| Setup of gateway | |

| Mobile communications | |

| Cloud usage fees (license fees for the next and subsequent years are not included) | |

| Gateway | Connect the control panel to the gateway, and install the gateway in a location with a good signal environment near the control panel. (This may vary depending on communication conditions.) |

| Data transmission volume | Standard : 20 points per gateway (1 minute interval) |

| Data storage period in the cloud | Standard : 13 months |

What Hosokawa Micron can do for the future

By using GEN4 RM, we can reduce the trouble and defective product rates, reduce the amount of raw materials used, and reduce CO2 emissions. In the future, Hosokawa Micron will continue to face the challenges of the global environment, and through its powder technology, will work for technological innovation and environmental protection for the next generation.