- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Cellulose (CMC)

Cellulose (CMC)

Summary

Cellulose and cellulose derivatives are made from plant cell wall, and are used as binder or as thickener in foods and pharmaceuticals. Cellulose derivatives are used in bakery, meat, fish or dietary food, whereas microcrystalline cellulose is used in low calorie food (salad dressing and desert). Cellulose is used in pharmaceutical industry as an expanding agent, which accelerates the release of active material or construction field.

Contents

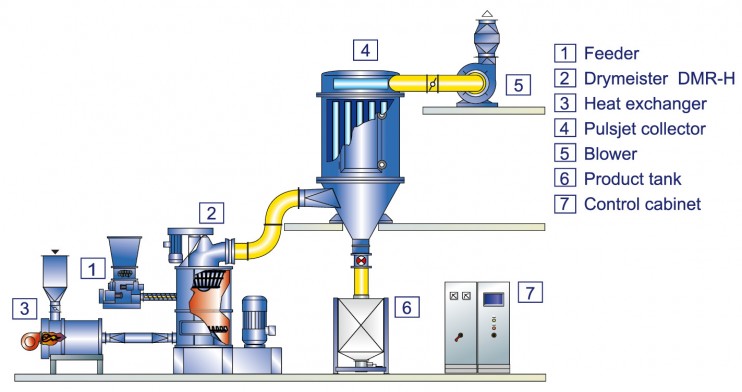

Fig.1 Flow of Drymeister

Fig.2 Drymeister DMR-1H

The grinding and drying flow of cellulose derivatives is shown as Fig 1.

The Drymeister DMR-H conducts fine grinding and drying at the same time. This system has a high production capacity, offering final product of d98 = 100 μm at the moisture content of below 5%. DMR-H has an air classifier integrated mill that can continuously produce fine dry product.

A cellulose derivative dry grinding system is shown as follows. The feed material has 3.2% moisture with below 1mm sizes. Required final product is d99.5 = 125 μm. This system consists of two stages. The cellulose derivatives are too hard material to be milled to the required particle size. The product from the first grinding process is to be ground and classified in the next process.

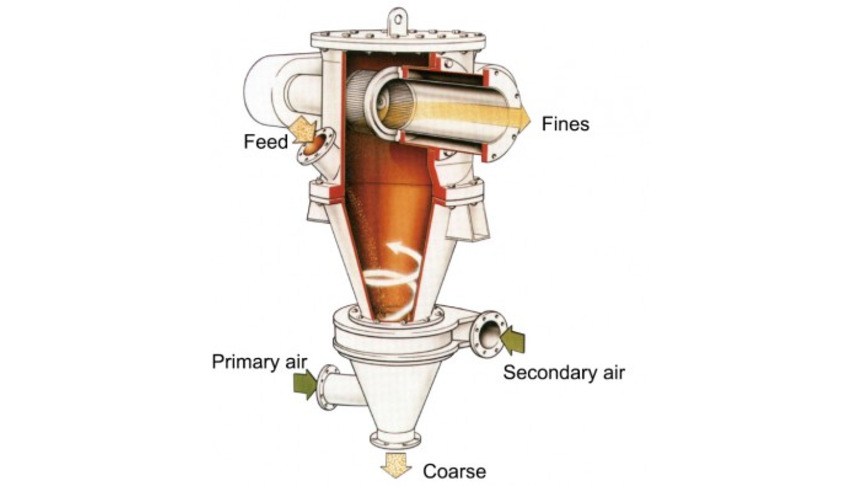

Fig.3 ACM Pulverizer

Conventionally ACM Pulverizer is used to grind cellulose to the size of 20-40μm, with standard type bar hammer. After incorporation of the newly developed vertically grooved hammer, capacity of ACM Pulverizer is increased by as much as 50%.

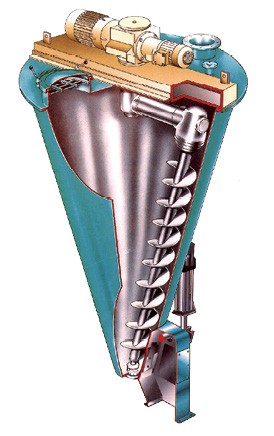

Fig.4 Vrieco Nauta mixer

Nauta mixer is used for Cellulose powder application, for the purpose of product quality stabilization. In this case volume of Vrieco Nauta mixer with 10-20m3 is commonly used. It was reported that Vrieco Nauta mixer is superior to conventional vertical shaft conical mixer in terms of mixing accuracy, which directly improves stability of the product quality.

Related equipments

Feel free to contact us. if you have any questions or concerns.