- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Baby Food, Powdered Milk

Baby Food, Powdered Milk

Summary

In the market of baby food or powdered milk, in order to cover the severe product quality standard, the latest information of high hygiene standards and the technology to mix components of a very small quantity at high reproducibility are required.

Contents

Various components of different bulk densities and ‘flowabilities’, such as vitamin, salts, metal complex, and amino acid at small quantities have to be precisely mixed for infant milk production.

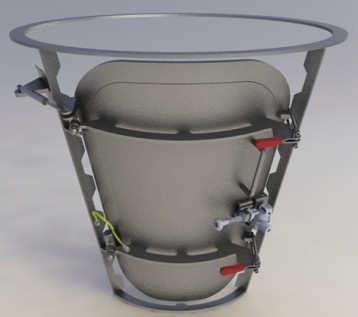

Fig.1 Big door

Fig.2 Vitomix VX-800

Fig.3 Sample taker

Fig.4 Ribbon screw

In the market of infant milk, the requirement of mixing preciseness is similar to the pharmaceutical product. Active ingredients are mixed with care depending on the maximum necessary intake. The most important is to guarantee that infants can take the nutrients precisely, when powdered milk is dissolved in water. For infant milk, the amount of each nutrient is the quality standard. It is too expensive to analyze each small batch. In order to reduce the analyzing cost of active ingredients, it is required to prepare a large batch production at least several tons. To fulfill the requirement for large process volume and precise mixing, Hosokawa proposes a mixer with cantilevered screw of sanitary design, big door for cleaning, sanitary sample bin, and sanitary design Hosokawa Isem valve.

Features

Fig.5 Structure of big door

We have a lot of references of the mixers producing infant milk. This production system requires high washability (CIP) and precision mixing. Also, it requires conducting mass batch production at the short process time and less damage to the product. Here, we introduce Vitomix, the best solution for this application.

Related equipments

Feel free to contact us. if you have any questions or concerns.