- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Nibbler NBS

Nibbler NBS

Summary

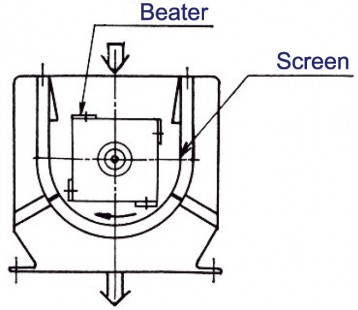

The NBS is suitable for shredding relatively soft agglomerates that may have been developed during drying, filtration process and/or from storing the material within a hopper or Silo. Products with particle sizes from a few mm to sub mm can be produced and easily controlled by simply switching the screen. The NBS is designed in a manner that allows the screen to be easily exchanged, as well as for easy cleaning and maintenance inspection. (Refer to Fig. Nibbler NBS 300/450)

Principle

Once the raw material enters the NBS, shredding and cutting forces are provided to it between the slowly rotating rotor and screen. Materials that are shredded and that pass through the screen are then collected as products. The rotors are set with beaters as seen in Fig.1. The position of the beaters can be changed to adjust the clearance between the beater and the screen. As seen in Fig.2, the interior of the screen is mountain-shaped which allows for cutting force to be applied to the raw material to help the shredding process. The size of the shredded product is adjusted by the screen’s aperture.

Fig.1 Section view

Fig.2 Easy detachable screen

Features

- The Raw Material can be easily fed into the machine due to its wide inlet.

- The inlet and outlet are concentric on a plane, allowing for easy positioning.

- Product sizes can be easily adjusted by switching screens.

- Due to the unique design of the screen, the residence time is short and generation of fines is minimized.

- Energy Consumption is low and the noise generated during operation is relatively quiet.

Feel free to contact us. if you have any questions or concerns.