- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- ACM PULVERIZER E-ACM

ACM PULVERIZER E-ACM

Summary

The ACM Pulverizer is a Fine Impact mill built-in with a classifier used throughout the world for fine grinding various materials. In carbon black grit reduction applications, the low bulk density of the material made processing difficult on standard ACM designs. Continuous innovations to the ACM resulted in a new system capable of reducing grit levels from several hundred ppm down to as low as 1 ppm.

Principle

Grinding mechanism and features

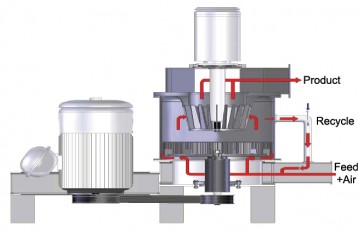

Fig.1 Grinding mechanism of E-ACM

Dispersion of the raw material is the most important aspect for grinding grit particles (coarse particles). The unit features a pneumatic conveying mechanism to effectively disperse and carry the raw material to the grinding chamber. To process light materials such as carbon, it is important that all of the raw materials flow through the grinding chamber. To assure that all materials pass through the fine impact mechanism, the E-ACM has a structure to feed the materials from the bottom of the grinding rotor.

Recycle-grinding of classified materials

There is a valve at the classifying section to discharge classified coarse particles back into the feed inlet using an ejector for re-grinding. The recycle percentage can be adjusted by controlling the ejector pressure. The suitable production condition is found through the balance between the product quality and capacity.

The explanation of this machine is also available by following movie.

Features

Grinding Efficiency

The grit amount within the product is affected by the grit amount found within the raw material. This unit can produce high-grade carbon blacks with a low investment and low running cost.

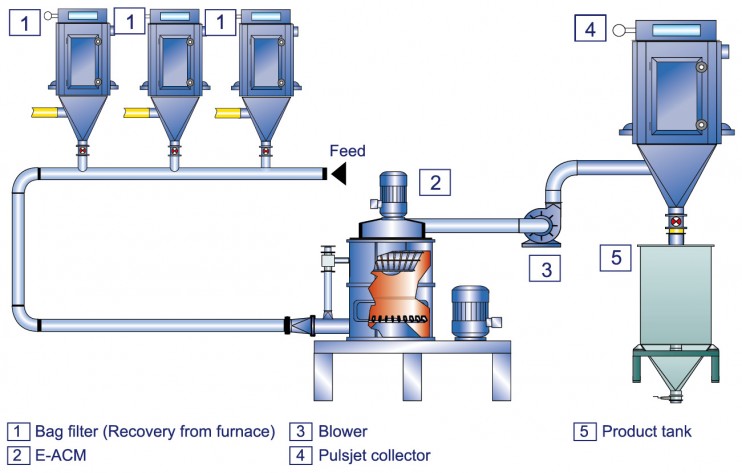

System

The grinding unit is normally incorporated into the carbon black process line as an in-line unit. The blower is installed directly after the grinding unit to compensate for the pressure loss generated by the E-ACM.

Fig.2 Grinding system flow of carbon black

Applications

The unique grinding/recycle mechanism of the unit can be used for materials other than carbon black as well. We have references in successfully providing energy-saving grinding for toner, powder coatings, flour, and soybean.

Specifications

Some models are available corresponding to the capacity of the carbon black furnace or reactor.

Related equipments

Feel free to contact us. if you have any questions or concerns.