- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- ACM Pulverizer Model CR[NEW!]

ACM Pulverizer Model CR[NEW!]

Summary

The ACM-CR is an ACM Pulverizer, widely used worldwide, with a high performance air classifier adopted from a jet mill. The result is a mechanical mill with performance approaching jet mill levels.

Principle

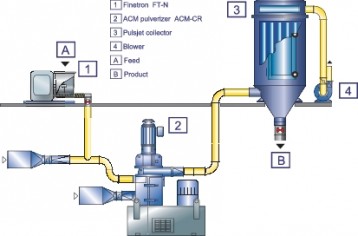

Fig. 1 Structure

The ACM-CR operates with the same principles as the conventional ACM Pulverizer. The ACM utilizes a closed circuit grinding mechanism, and can re-grind the returned coarse material by the strong impact forces generated by the hammers and liner. The grinding rotor efficiently grinds material fed through the feed inlet. The ground powders and unground feed materials are pneumatic conveyed to the integrated classifying section by the circulating airflow. The fine powders are discharged through the classifying wheel and are as product. The coarse material drops down along the guide ring back to the grinding chamber due to centrifugal force of classifier. ACM-CR achieves ultra fine grind with the combination of high speed grinding disc with specially designed hammers, and a unique built-in high performance classifier.

Fig. 2 Flow

Features

High grinding ability

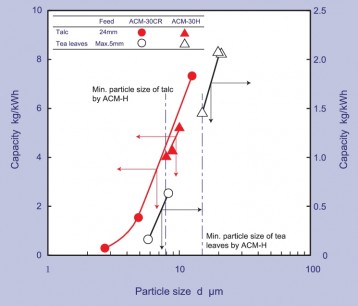

Fig. 3 Comparison with conventional ACM (ACM-H)

It is available to ultra fine region approaching jet mills.

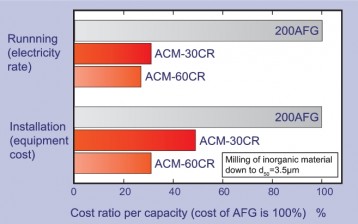

Reduction of running & installation

Fig. 4 Costs comparison to jet mill

costs (Compared with jet mills)Lower costs, due to mechanical grinding principle of ACM-CR, that doesn't required expensive to run compressor

Easy to adjust particle size

Adjusting particle size during operation is just a matter of the rotating speed changing of classifying wheel and adjusting air volume.

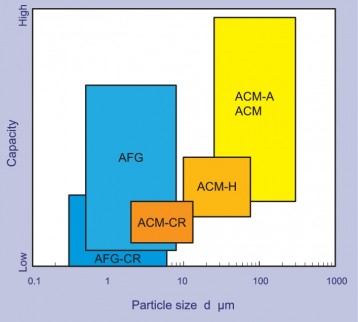

Fig. 5 Selection diagram

Applications

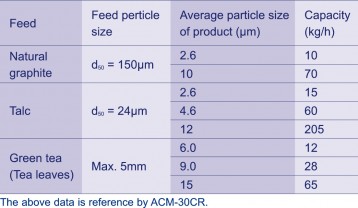

Table 1 Applications

ACM-CR works on the same principle as the ACM Pulverizer and has the same wide range of applications.

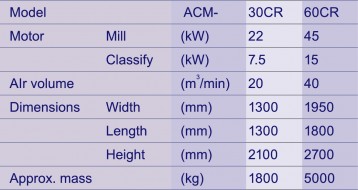

Specifications

Table 2 Specifications

Related equipments

Feel free to contact us. if you have any questions or concerns.