- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- FACULTY S Series, F-S

FACULTY S Series, F-S

Summary

Value adding Faculty; spheronization, densification, rejection low value particles on powder is realized. Typical applications are toner and graphite. (anode for LiB)

Spheronization of toner has conventionally been conducted by thermal technology after dedusting process. This requires two stage processes (some piece of equipment) and gives thermal damage to toner. In the semi-batch operation of Faculty, the feed is dispersed and spheronized by unique designed rotor and dedusting by newly developed classifying wheel. These operations are repeated again and again in a cycle to need the required shape and size.

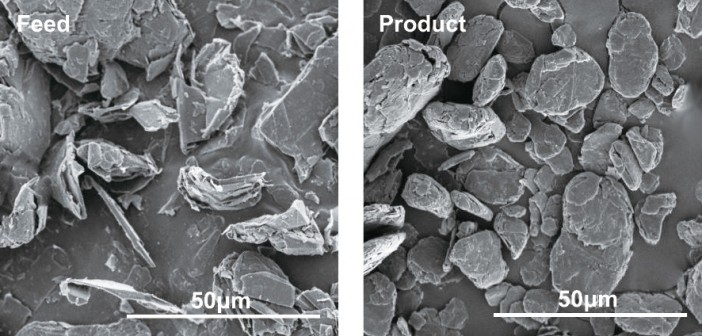

This process is also applied for graphite. The graphite is processed as same as toner is conducted, The major purpose is the densification. As a result of spheronization, the bulk density of graphite is increased by 70%. Spheronization, densification and dedusting is carried out simultaneously. The densified graphite improves the performance of LIB. New "S" series provide 4 models and a ceramic version for a certain models.

(FACULTY is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

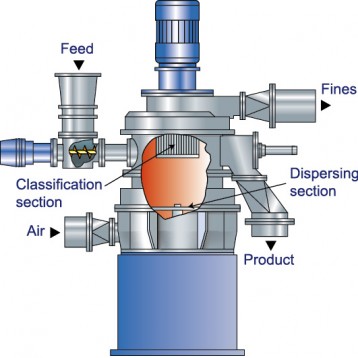

It consists of the dispersion zone where energy input to powder is controlled by the rotor speed. In the classifying zone, very fine particles are rejected by the forced vortex type classifier and the coarse product outlet locates at the side of the casing.

During the semi-batch operating mode of Faculty, the material receives energy from dispersion rotor for the period of a few minutes. At the same time, the fine particles are separated by the classifier. The spheronized product is discharged from the Faculty. Thus, a semi-batch cycle of the feeding, spheronization/dedusting and discharging is completed.

Top size is controlled by the classifying rotor speed. Casing can be provided with the jacket for cooling/heating media. Faculty "S" series provide pneumatic discharging mechanism which drastically improves the process capacity.

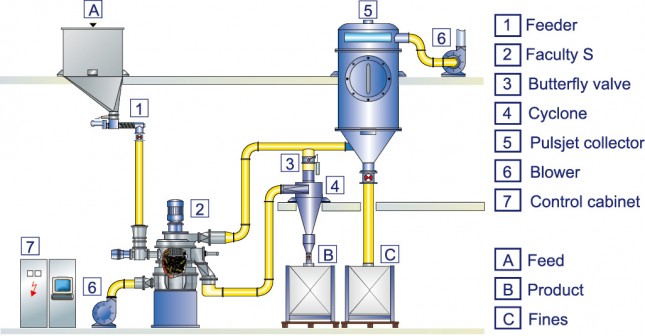

The plant consists of the feeder, Faculty, pushing blower, cyclone, Pulsjet collector and an aspiration blower. (Please refer Fig.2)

Fig.1 Schematic structure

Fig.2 Flow for spheronization of graphite by Faculty

Features

- Multi Functions: Dedusting, Surface treatment, Spheronization, Densification, Separating impurities in one cycle

- Possibility in simplifying process

- Operator friendly equipment (easy adjustment of parameters)

- High performance new classifying wheel is loaded in S series.

Applications

Typical industrial applications are toner spheronization and graphite (LIB anode) densification.

Densification of graphite improves packing volume and overall LIB performance.

Densified graphite gives high energy density of LIB.

Dedusting and surface treatment reduces the specific surface area which leads simplified LIB manufacturing process.

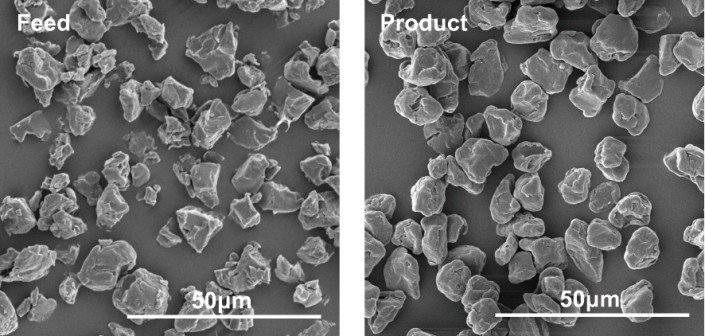

Spheronization of toner

Conventional toner spheronization (thermal process) requires the dedusting toner. This requires complex process and results with thermal damage of wax/binder. Mechanical spheronization and dedusting are simultaneously conducted by Faculty.

Fig.3 Toner Feed>Product

Fig.4 Natural graphite Feed(0.5g/ml)>Product(0.85g/ml)

Feel free to contact us. if you have any questions or concerns.