- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- NOBILTA NOB, NOBILTA VERCOM NOB-VC[NEW!]

NOBILTA NOB, NOBILTA VERCOM NOB-VC[NEW!]

Summary

The Nobilta is high performance powder processing machine used for particle design. It is capable of a wide range of fast mixing from macro mixing to micro mixing, particle composing, surface treatment and spheronization.

Nobilta Vercom (NOB-VC) is the dry particle composing machine that realizes large process capacity while maintaining the superior composing ability of conventional Nobilta (NOB).

It can realize the large process capacity and compacting while maintaining the ability of NOB, by optimizing the structure.

Moreover, cleanability is significantly improved.

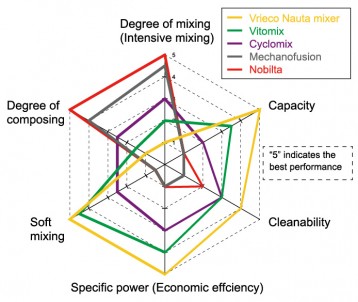

Typically with mixing / dispersion, the 3 mechanisms of convection, shear and diffusion are required, but in the case of composing of Nano-particles, an additional strong mill like mechanism (impact, compression, attrition) is required to overcome the strong agglomeration force of the Nano-particles. Typical mixers are biased towards one of the 3 mechanisms of mixing and either do not have the capability of composing requiring an additional composing machine, or do not have the ability to disperse Nano-particles resulting in agglomerates in the product. This resulted in no being able to achieve the target particle.

With the Nobilta, the combinations of compression, shear and impact forces are applied to the particle resulting in Nano-particles being composed efficiently without binder. The world leading composing performance of the Nobilta is in use in a wide range of industrial fields.

(NOBILTA is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

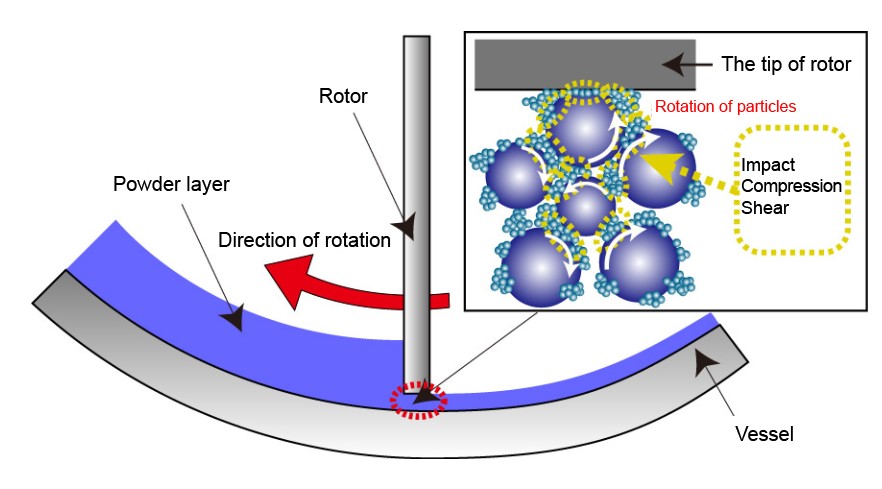

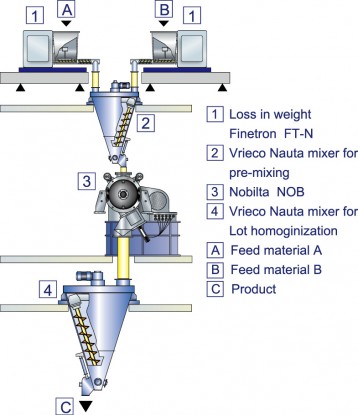

Fig.1 Principle

It is so designed that impact, compression and shear force work on each particle with the uniquely configured rotor.

This configuration of rotor as well as internal arrangement is the know-how of the uniform composing. By the adjustment of the rotation speed and operational time particle processing (composing and precise mixing) is carried out.

The cooling jacket is provided on the vessel for prevention of the sticking and degradation of product quality.

Optional parts are available for processing of abrasive materials.

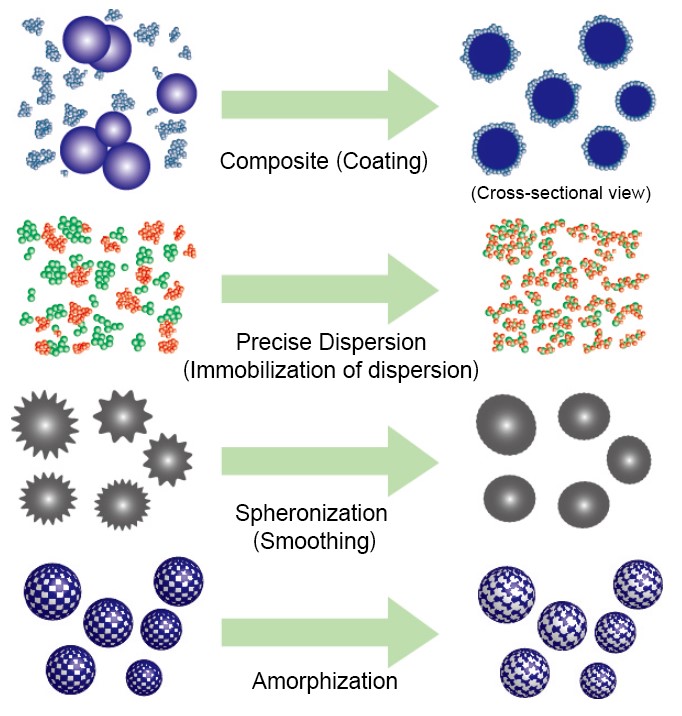

Fig.2 Image of particle design

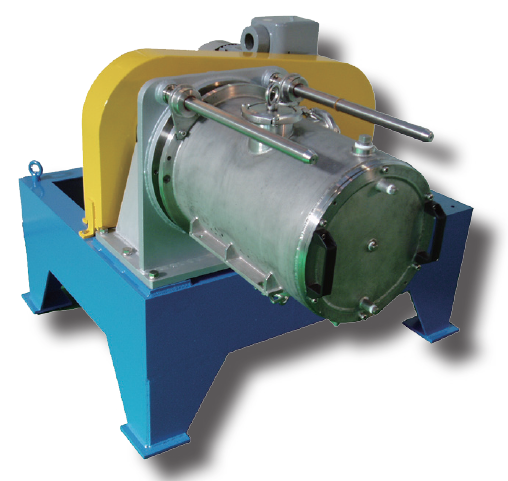

Fig.3 NOB-1000VC

Fig.4 NOB-700

Fig.5 NOB-300

Fig.6 NOB-130

Fig.7 NOB-MINI

Features

Fig.3 Selection chart / Mixer

- One machine can be used for mixing, composing, surface treatment, and spheronization

- Nobilta can be used for particle design of Nano sized particles.

- Nobilta can be used to mix a wide range of particle sizes from Nano level to micron sizes.

- Compact, low running cost

- Easy to disassemble, clean, and reassemble

- Nobilta can process heat sensitive, abrasive, sticky, hard to handle materials

Applications

Batteries, Capacitors

- Improve performance of LIB, Fuel cell, Electrode of capacitor, Solid electrolyte, etc.

Magnet materials

- Improve packing density and coercivity of high performance magnet

Pharmaceuticals

- Masking treatment, Microcapsulation of oral dispersing tablets

Ceramics

- Electronic materials. Dental materials, Ultrahard materials

Heat related materials

- Improve thermal insulation performance or heat transfer

Chemicals

- For the development of composite polymers (Nano-filler, etc.),

- Increase catalyst performance, Increase sintering performance

Photocopy

- Increase flowablitiy of toner, Surface treatment of carrier particles. (Coating, etc.)

Others

Fig.4 Flow

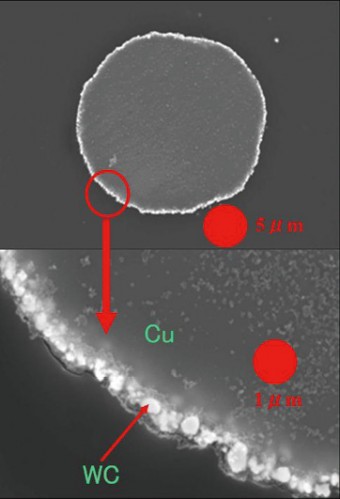

Fig.5 Example of composite particle (Copper particle coated by tungsten carbide nano particles)

Feel free to contact us. if you have any questions or concerns.