- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Extrudomix EM

Extrudomix EM

Summary

The Extrudomix is a continuous screw shaped extruder to mix liquid with powder. It consists of a paddle shaped screw, anvils and orifice plates located at the middle and the end of the casing. The mixed material receives strong sheer force by the internal parts. Because of its high kneading ability, there is no premixing (powder/liquid) is required. Changing the size of orifice plate holes from 1 to 30mm can control size of agglomerates. As the agglomeration is preceded by extrusion through the orifice plate, cylindrical product is obtained with high hardness and at high yield.

Principle

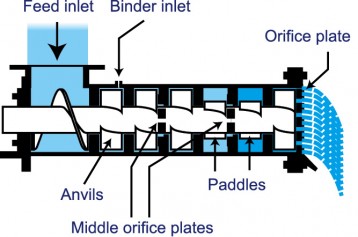

The Extrudomix consists of a single horizontal shaft with paddle shaped screw arranged in a spiral pattern, which drives the material through the chamber. After material gets enough plasticity by mixing and kneading effect, it is extruded out from orifice plate. Screw shape at the feeding part is full blade, paddles with angle of torsion at the liquid mixing part. Anvils are positioned inside the casing to give sheer force to the powder. Two orifice plates are located at the middle of the casing to increase the sheer force to the material. The end orifice plate size should be smaller than that of the feeding side. If no kneading is required, orifice plate at the end can be taken out.

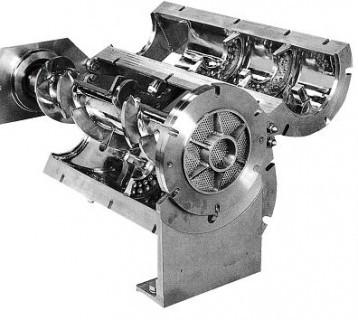

Fig.1 Extrudomix EM-10 in pharma design

Fig.2 Schematic structure

Features

Cylindrical and hard agglomerates

Uniform cylindrical product can be produced. Hardness prevents agglomerates from collapsing.

Easy control of agglomerates size

Agglomeration size can be adjusted by changing the orifice plate.

High kneading ability

Strong sheer force to the material by the internal parts; screw paddles, anvils and orifice plate of the middle.

Possible to process several materials at once

Stable mixing and kneading of several materials and liquid.

Improve powder handling

Densification and dust free products.

Continuous process

Applying quantitative feeding system for powder and liquid. Together with continuous drying process, continuous and automatic operation is possible.

Easy cleaning

Adopting top-bottom open casing with hinged configuration, disassembling and cleaning become easy.

Feel free to contact us. if you have any questions or concerns.