- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Air Jet Sieve MAJSx2

Air Jet Sieve MAJSx2

Summary

The Mikro Air Jet Sieve, Model X (MAJSx) is an economical particle size analyzer designed for chemical, mineral, food, pharmaceutical and cosmetic materials ranging from 20µm to 4,750µm. The MAJSx is easy to operate and quickly determines particle size with a short series of sieve test screens. The system utilizes the pneumatic sieving principle that enhances the accuracy and reproducibility of particle size analysis. Use of this device has become a preferred method for tasks such as quality assurance of incoming raw materials and the confirmation of final product specifications.

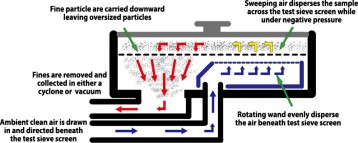

Principle

While negative pressure draws all the particles below a defined particle size down through a sieve screen, a positive airflow is introduced upwards through a rotating nozzle. This airflow de-agglomerates and disperses undersized particles and carries them to the vacuum collector.

This rotating nozzle method also eliminates the need for tapping or brushing and increases reproducibility with controlled measurements of pressure drop and duration. This device has become a preferred technology for such tasks as quality assurance of incoming raw materials, confirmation of final product specifications, and the efficient and trouble-free use of determining particle size.

Fig.1 Connection socket to vacuum cleaner

Fig.2 Structure

Features

- Suitable for chemicals, minerals, pharmaceuticals, food, plastics & cosmetic applications

- Determines particle size for dry powders from 20μm to 4,750μm

- Economical to own and operate for easy, fast & accurate analysis

- Capable of calculating particle size points at 0.01 to 99.99% using the Rosin-Rammler Law

- Suitable for operation on 100-240 volt, 50/60 Hz power

- Compact device measures 12” wide x 15” deep x 13” tall, and weighs 23 pounds

- Samples 10 to 100 grams/cycle

- Brush, 200mm diameter test sieve cover and tapping hammer included as part of the standard scope

- Suitable for use with ASTM and ISO Certified test sieve screens

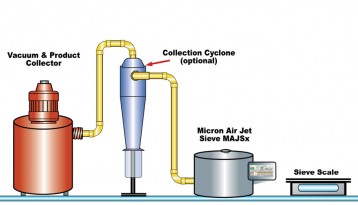

Fig.3 Standard set up with optional cyclone

Fig.4 Interior of MAJSx

Fig.5 Touch screen

Other information

- Cyclone for up to 99.5% product recovery over 10μm

- Suitable for 200mm and 203mm test sieve screens

- Multi-screen adaptor capable of analyzing 3 samples simultaneously

- Vacuum system designed for safe, consistent and reliable performance

- HEPA vacuum available for high containment operation

- Electronic balance for accurate & complete particle size analysis

- Validation services available upon request

Fig.6 Cyclone

Fig.7 Multi-screen adaptor

Fig.8 Vacuum cleaner

Feel free to contact us. if you have any questions or concerns.