- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Powder Characteristics Tester PT-X

Powder Characteristics Tester PT-X

Summary

The Hosokawa Micron Powder Characteristics Tester called as “Powder Tester” is measuring instrument for the indexes of the “Flowability & Floodability” of dry powder. They were defined by Mr. R.L. Carr (Carr Index) to measure 10 individual powder characteristics, such as angle of repose, cohesion, bulk density and to calculate using with Carr’s index table. Mr. Carr (American mining engineer) has measured more than 1000 powder samples to complete the Carr’s Index Table.

Hosokawa Micron Corporation has developed “Powder Tester” as powder characteristics measuring evaluation. Since the first model of “Powder Tester” PT-A commercialized in 1969, the model changes have been repeated. More than 4000 units have been delivered to the customers and have been working all over the world. The customers are using the “Powder Tester” for the purpose of product quality control, design and optimization of production process, or new material development in various business fields, such as secondary battery material, toner or pharmaceutical materials. Hosokawa has completed the PT-X as the 9th model for reflecting the voice of worldwide users. It realizes “global standard of powder characteristics evaluation” by improving accuracy, repeatability, and easier operation.

If you would like to know "Why I need to numerical evaluate powder?", "Why other method is not suitable?", click "Here"!

Principle

Measurable characteristics

Bulk density and related values

Aerated Bulk Density, Taped (Packed) Bulk Density. Compressibility

Angles

Angle of Repose, Angle of Spatula, Angle of Fall and Angle of Difference.

Others

Cohesion or Uniformity and Dispersibility

Options

Equilibrium tapped bulk density

It is measured manually till the packed volume converges within the set value.

PSD measurement (JIS compatible)

Gives the diameter of d10, d50, d60 and d90 respectively by sieving. The unit can be mounted with maximum 12 stages of sieve drums.

Automatical measurement of tapped density based on USP, JP, ASTM and Kawakita’s method

The unit (Fig.1) can measure automatically the tapped density with graduated measuring cylinder (USP, United states of Pharmacopoeia). This unit can also supply the others measuring methods of tapped bulk density, such as based on JP (Japanese Pharmacopoeia), ASTM (America Society for Testing and Materials) and Kawakita’s evaluation method. This unit can automatically monitor the powder volume by image analysis and the charging continues till the preset point.

Fig.1 PT-X integrated with automatic measurement of taping density

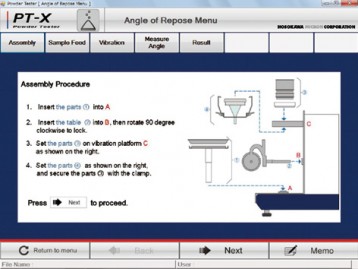

Fig.2 Example of operating screen

Fig.3 Various flowability for each powders

Features

Easy operation

Operator friendly monitor instruction and the improved parts design. Total operation time is shortened to 77% compared to the previous model (For this model, total 20 minutes to complete all the analysis.)

No individual operator’s error by following operating instruction shown on the PC monitor (Fig.2) 5 languages are available, Japanese, English, German, Chinese, or Korean (All overseas languages are available as option). The operating software has new functions such as CSV output of the data, controlling the access level to the data, etc. to satisfy the customer’s requests.

High accuracy and reproducibility

Fully redesigned the moving parts such as vibration and tapping parts give high accuracy. PT-X minimizes a personal error such as measurement of angle or falling motion by shocker. Storage of every measuring condition repeats to set the same condition as the past.

Dedusting function

PT-X is designed for air tight structure to prevent a leakage of dust. For the dusty powders, vacuum cleaner can be connected to the PT-X to aspirate the ambient. Optional manual sampling feeder helps to feed the material without opening the enclosure while operating.

Measurement of small volume sample

Optional small table for measurement of angle of repose and bulk density cup can apply for small volume sample.

Statistical analysis software (equipment supplied since 2018/12)

Dedicated statistical analysis software(equipment supplied since 2018/12)

It is possible to easily analysis by only reading measured results obtained by PT=X is available without high level kwnoledge.

Following three values can be easily obtained by this software.

- Representative values of data ( Average, Standard deviation)

- Difference between data (Statistical significance test)

- Relationship between data (Correlation coefficients)

Applications

Hundreds of science and engineering articles use the measuring data from the series of Powder Characteristics Tester.

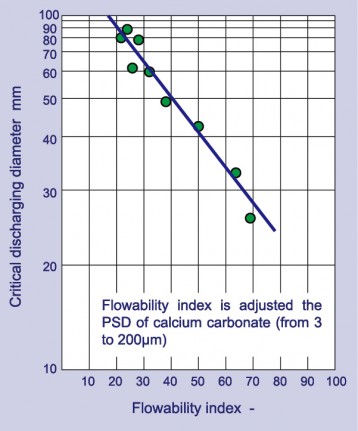

Relationship between critical discharge outlet and flowability index (Fig.4)

Fig.4 Relationship between critical discharging diameter and flowability index

The difficulty (bridging level) of discharging the powder from a hopper as a dischargeable minimum diameter, it introduces the following relationship. (11th Proceedings of the symposium on powder science and technology, vol.36, 1977)

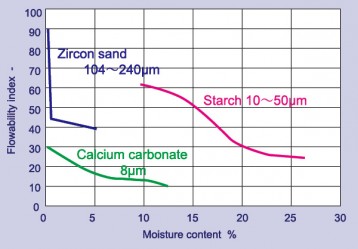

Moisture and flowability index (Fig.5)

Fig.5 Relationship between moisture content and flowability index

The moisture content of the powder greatly affects the flowability index. Varying moisture causes troubles in handling the powder because of the change in flowability index corresponding to the moisture. In order to prevent such trouble, it is necessary to understand the influence of moisture content to the flowability index. (Kagaku kikai gijutsu, vol.22, 155, Soc. of Chemical Engineers, Japan, 1970, Maruzen Publishing Co.)

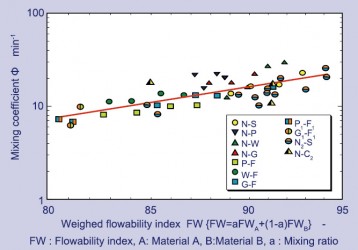

Mixing speed and flowability index (Fig.6)

Fig.6 Estimation of mixing coefficient by flowability index

It is important to consider the coefficient of mixing speed in mixing process. The flowability index of powders affects to the mixing coefficient, PT-X gives the policy to the controlling mixing process by applying the relationship between the flowability index of powder before mixing and the coefficient of mixing speed. (Journal of the Society of Powder Technology, Japan, vol.9, 82, 1972)

Note: In a mixing curve displayed on a graph with the mixing time t on the horizontal axis and the degree of mixing (standard deviation) σ on the vertical axis (in logarithmic notation), the logarithm of the degree of mixing shows a linear relationship to the mixing time in the initial stage of mixing. In other words, the mixing rate equation becomes a linear function. The absolute value of the gradient is called the coefficient of mixing speed φ.

In other words, dσ/dt = -φσ (in the initial stage of mixing), and if we assume that σ = σ0 under the initial condition t = 0, the solution to this differential equation is σ = σ0・exp(-φt), which allows us to calculate the mixing degree (standard deviation) σ.

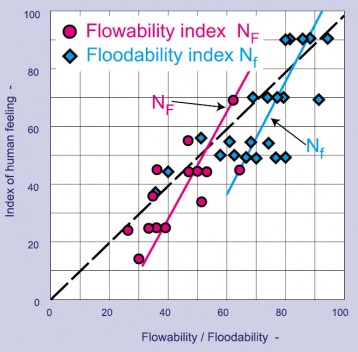

Relationship between human feeling and flowability and floodability indices (Fig.7)

Fig.7 Relationship between flowability index and human feeling

A pharmaceutical company conducted a detailed investigation as to whether the flowability and the floodability indices determined by the Powder Characteristics Tester conform to the feeling of persons actually handling the powder. The authors reported that the flowability index obtained by intuitive methods conforms to the results obtained by Powder Characteristics Tester.

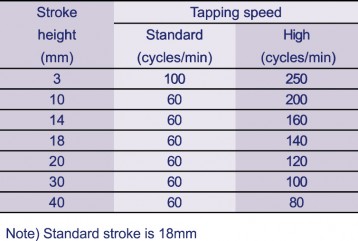

Table 1 Specifications of tapping function

Tapping condition is adjustable.

Table 1 shows the range.

Other information

Attention

Dear Customers,

Thank you for using our Powder Characteristics Tester PT-X.

We found a few customers have a problem of the deterioration of the damper which is supporting the acrylic cover.

This is because, the PT-X was started to deliver six years ago.

We adopt the design applied the damper for the acrylic cover of PT-X to prevent accidents such as finger stuffing by conforming to the CE marking.

Therefore, repeating the forcibly closing of the cover by applying force more than its own weight will accelerate the deterioration of the damper.

Accordingly, please close the cover by its own weight after closing it to 45 degrees manually.

Please contact our sales representative or the following contact address, if you have doubts that the damper is not operate sufficiently.

NOTICE: Support Services for the Hosokawa Micron Powder Characteristic Tester model PT-S

As of 31st October 2019, due to the increasing difficulty to procure Replacement Parts for the Hosokawa Micron Powder Characteristic Tester model PT-S, Parts and Support Services for the model PT-S will no longer be available.

In the event the current part supply become exhausted, support may terminate earlier than 31st October 2019.

Should you have any questions please don’t hesitate to contact us.

Feel free to contact us. if you have any questions or concerns.