- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Air Jet Sieve e200LS

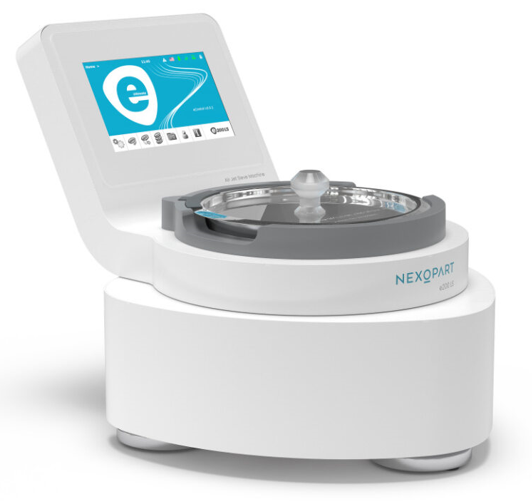

Air Jet Sieve e200LS

Summary

Hosokawa developed the process of air jet sieving over 50 years ago and launched the very first air jet sieve onto the market. Every new generation constituted a milestone with which Hosokawa defined new standards for particle size analysis.

Today, the Alpine Air Jet Sieve is the most-used device around the world for determining particle size distributions to permit production monitoring and quality assurance as defined in DIN EN ISO 9001, as well as for the validation and documentation of tests in the laboratory. The Alpine Air Jet Sieve is also stipulated as standard test equipment in the factory standards of companies throughout the world. Numerous domestic and international standards also mandate the air jet sieve as the testing device for certain products.

Principle

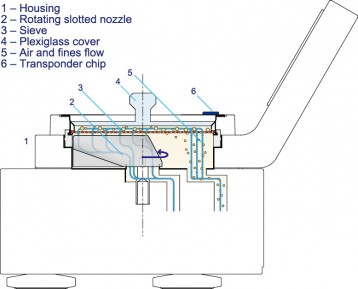

The only thing that moves the material being analyzed is the air flow. The strong jet of air exiting the rotating slotted nozzle purges the sieve gauze continuously.

This leads to exceptionally short sieving times and ensures that even those materials which are known to cause difficulty can be sieved successfully. At the same under pressure and same sieving duration, exactly reproducible particle size analyses are possible at any time.

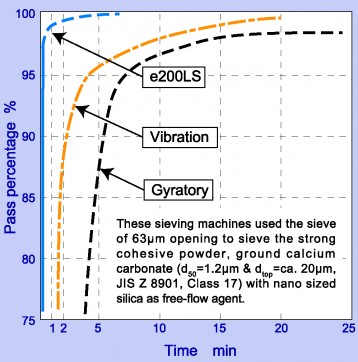

Sieving time comparison between e200LS and conventional test sieve is shown in Fig.2.

Fig.1 Schematic structure

Fig.2 Comparison of performance

Principle of Operation

Features

Fig.3 Powder

Efficiency at work

This means that all the standard functions and evaluations are already integrated into the new e200LS. The user-oriented system interface makes operation easy and reliable.

Operational procedures are faster and work is more comfortable, and you save on peripheral equipment.

Integrated under pressure controller

The e200LS has an automatic controller that monitors the under pressure in the sieving chamber and thus the dispersing effect of the nozzle jet, and which keeps the under pressure constant throughout the entire sieving process. Here too, this means: more efficiency, reliability and comfort.

Universal sieve adapter

Simply switch over to the new e200LS: all sieves can be used, regardless of make and 200-LS version.

Sieve identification

Alpine sieves equipped with a transponder chip are recognized and identified by the integrated software. Manual input of the sieve mesh width is no longer necessary, thus reliably preventing sieve insert errors. Evaluation in the analysis log is automated. This is particularly advantageous for laboratories in which a number of different products are analyzed with different sieve sets. Process parameters such as sieving time and under pressure can be individually saved to memory and retrieved automatically during operation.

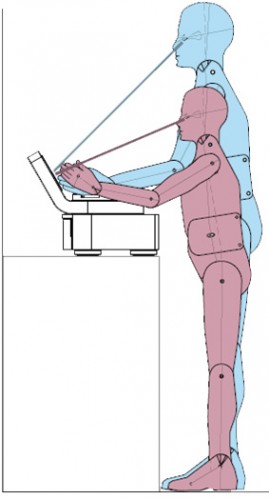

Ergonomic design

Fig.4 Ergonomic design

And last but not least: the elegant and fluid lines and the smart touch screen.

You only need to glance at the new e200LS to see that it is a high-end model

=embedded system

an integrated minicomputer with eControl regulates, monitors and controls the entire process

=easy

intuitive operation using a touch screen

=efficient

time savings brought about by optimization of the sieving times

=ergonomic

functional, elegant design

=evolution

continuous and ongoing development from generation to generation

Easy operation

Fig.5 Touch screen

Simply get started – the user interface makes intuitive operation possible. The integrated analysis guide leads you through the analysis and moreover offers:

- Comparison analysis, trend analyses for statistics

- Language switch-over and setting of country-specific measurement units

- QM-Toolbox with user administration and password protection

- Recipe management for sieve sets

- Archiving and export of analysis results

- Compliance with 21 CFR Part 11

Reliable quality

To sum up, the new e200LS guarantees results of outstanding quality because the integrated modules eradicate any error sources. This means a significant increase in user reliability, sample reliability and data reliability. All the latest quality standards are met.

Fig.6 Startup screen

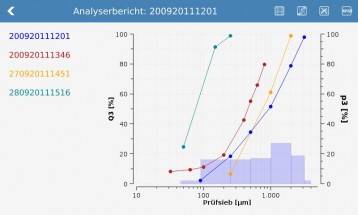

Fig.7 Example of measurement

Fig.8 Example of PSD measurement

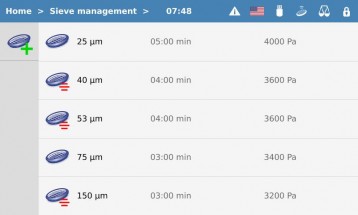

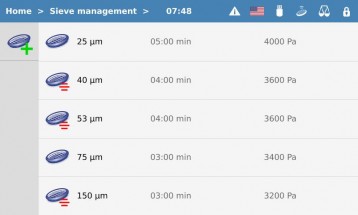

Fig.9 Sieve administration

Fig.10 Test sieve management

Applications

- Particle size analysis

- Control very coarse particles

- Confirming all passing

- R&D

- Pharma Carrier (JP No.13) or later

Sieving of commercialized cement powder (The announcement is Japanese only)

=Control

The new e200LS is controlled by eControl.

The software is available in three variants:

Lite

Simple and cost-effective type

Basic

for all fundamental sieving processes

Professional

the variant for all standard laboratory requirements

Ultimate

top-drawer software for special demands

Feel free to contact us. if you have any questions or concerns.