- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

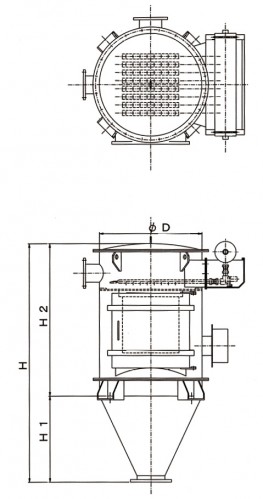

- Sinter Pulsjet Collector PSLC

Sinter Pulsjet Collector PSLC

Summary

The Hosokawa Micron Sinter Pulsjet Collector is the pulsejet cleaning type dust collector with filter elements made from sintered composite plastic. The filter surface is coated with PTFE so collection efficiency is very high and the dust release is superior. Because cross sectional form is corrugated, filtering area per filter unit is large, resulting in space saving. High vacuum design is adopted on the housing, coping with powder collection application for pulverizing or classifying. Suitable for material with severe exhaust gas control or use in severe environment.

Features

The filter used in this product has following features

High collecting efficiency

High collection efficiency because filter surface area is very fine due to PTFE coating. Dust release property over the element surface is good and dust accumulation over the filter is minimum so powder collection is very high yield.

Compact

Due to corrugated cross sectional form filtering area per unit is large.

Stable pressure drop across filter

Dust release property is high because of PTFE coating thus pressure drop is stable.

Easy maintenance

Filter mounting/release is very easy since filter is fixed at both ends with only 2 pcs of bolts.

High durability

Because filter strength is high, it is possible to use at high pressure drop, which is not possible with common filters.

Heat resistance, anti-static filter

Standard is for heat resistance at 70°C (SL-70) with option 160°C (SL-160). Filter with anti-static finish is also available.

Fig.1 Element

Fig.2 Dimensions

Applications

- Product collection and exhaust gas from toner manufacturing plant

- Product collection and exhaust gas from powder coating plant

- Product collection of fine powder

- Product collection in height limitation

The model available for the filter area of 4.8m2-72m2.

Feel free to contact us. if you have any questions or concerns.