- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Pulsjet Collector, High Vacuum Type CP

Pulsjet Collector, High Vacuum Type CP

Summary

The Hosokawa/Micron Pulsjet Collector is a dry dust collector, collecting powder from dust laden air through filter media by intermittent, momentary, pulsejet cleaning energized by compressed air. The Pulsjet Collector is widely used in product collection of powder handling equipment such as pulverizers and classifiers with high pressure drop, and pneumatic conveying with the use of high pressure blowers, where high pressure design of the bag filter itself is required. Since the housing is made in a cylindrical shape, it has high pressure capability with little reinforcement, minimum powder trapping and high cleanability. Because of its design with minimum powder trapping, it has the advantage that explosion vent area can be reduced in case of collection of powder, which has explosion risk.

Principle

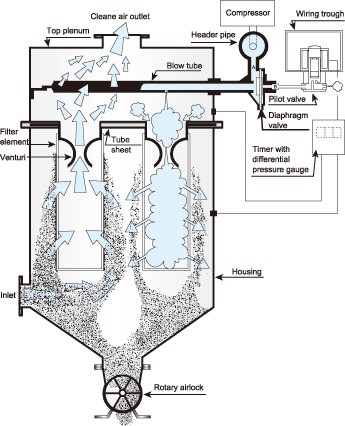

Fig.1 Principle of Pulsjet collector

Consists of a filter part, which collects powder, a blow-off part where pulsejet compressed air is stored and jetted, and a housing that holds these parts and a timer which controls pulse-jet action. Blown-off powder is continuously discharged.

Filter

A dust laden gas flow through the filter from outside to inside and the powder is collected at the outer surface of the filter. Gas passing through the filter becomes the “cleaned” gas and the collected powder is discharged to outside though the discharge outlet. Usually cylindrical felt fabric filter is used, however, space saving type, pleated elements (K type), has a larger filter area per unit and can be utilized well. In case of felt filters, metal retainers are inserted inside to hold the cylindrical shape. Filter material is selected depending on the type of powder, gas temperature, and gas composition.

Blow-off mechanism

Consists of a header pipe where compressed air is stored, diaphragm valves which blow-off the air in the header pipe in very short time, pilot solenoid valve which exhaust a little amount of air to activate the diaphragm valves and blow tubes through which compressed air is discharged to the filters. Suitable cleaning cycle specification is decided depending on total filter area and the pressure of the compressed air.

Housing

A top plenum which holds the blow-off part, a tube sheet which holds filters and separates clean and dirty sides, a straight body part which contains the filters, and a hopper part where powder is collected and conveyed to a discharge. Material is selected depending on the application of the powder, gas temperature and gas composition. Usually general purpose rolled steel (SS400) or stainless steel is used as construction material.

Timer

It contains the circuit board, which controls the pilot solenoid valves and sets the on/off time. Options can be selected such as display of pressure drop across the filter, differential pressure control mechanism, which activates pulsejet when the pressure drop reaches the predetermined pressure, or differential pressure signal transmitter.

Discharging

During operation there is differential pressure between inside and outside of the bag filter, the internal collected powder should be discharged while correctly air-locked. In case of high vacuum Pulsjet Collector, because of high differential pressure between inside and outside of the bag filter, a double damper or a high seal type rotary valve is used.

Features

Depending on requirement various models are available with various filter areas, shapes, and filter replacement methods.

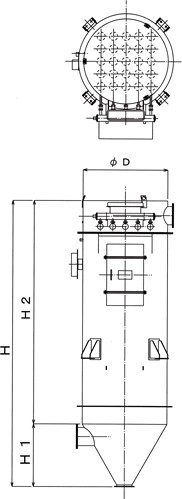

CP Type

Small bag filters with filter area up to 88m2. Maximum design pressure is 55kPa in this series. These units can be shipped completely assembled. Filter replacement is done from the side (side removal type). This type is suitable for use when there is height limitation.

CP type is available for the filtering area of 6m2~87m2.

CP-K Type

A cartridge filter, which has larger filter area per unit, is mounted in the CP type cylindrical housing. Maximum filter area is 202m2. Large filter area is available with small installation space.

CP-K type is available for the filtering area of 12.3m2 ~ 202m2.

Applications

- Product collection from vacuum dryers

- Product collection from pulverizers

- Product collection from classifiers

- Product collection from dryers

- Vacuum cleaners

- De-dusting in natural gas piping

Specifications

Fig.2 Dimensions of CP

Feel free to contact us. if you have any questions or concerns.