- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Industries Search

- Handling for Pharmaceuticals and Nano Powder

Handling for Pharmaceuticals and Nano Powder

Summary

The development of increasingly active substances as well as the tightening of corporate and statutory regulations with regard to personnel protection result in ever-higher requirements to protect personnel from contact with these powdery active substances. To meet these requirements, a great variety of different systems have been developed over the last years, which create a barrier between the operator and a possible dust exposure. We are talking here about so-called isolators, which represent an enclosed housing around the process units where a dust exposure is considered likely.

Contents

Processes realized with isolators:

- Sampling

- Particle size analysis

- Filling

- Metering

- Grinding/micronization

- System component cleaning

The integration of processing systems into isolators poses high engineering demands. When customizing an isolator, the following points must be paid particular attention to:

- Transfer port system concept

- Operator-friendliness (ergonomics)

- Product yield

- Cleanability

The isolator must be integrated into an existing product flow, meaning that special attention must be paid to the process steps upstream and downstream of the isolator. The method and shape of the feed or filling containers have a decisive influence on the transfer port concept. Dependent on the batch size or OEL, double-flap transfer ports (RTPs) or continuous liner systems are available.

One of the greatest challenges when integrating processes into isolators is to ensure that the entire system can be operated comfortably, i.e.ergonomically. This simple statement puts extreme demands on the manufacturers of complex systems in terms of design of both the process components and of the isolators.

Fig.1 Spiral jet mill 100AS for batch sizes of approx. 0.5-3kg on the R&D sector

After 3D-CAD modeling, a wooden mock-up is usually made which depicts the most important process sections and which serves to determine the final design.

One advantage of integrating processes into a containment system is that the contaminated cubic volume is significantly reduced. After all, it is not the complete clean room with the associated interior that is contaminated but rather "only" the inside of a steel box.

And to counter this, isolators are equipped with cleaning systems. These systems generally comprise ducting that taper into spray nozzles in the inside of the isolator. In addition, a spray pistol is used in most cases.

The know-how gathered by the Hosokawa Group in this field over the years has put Hosokawa in the position of being able to supply complete systems, which considerably reduce the customer's planning and coordination complexity and which ensure reliable system operation. The realization of numerous containment projects as well as the close cooperation with the customer highlight the competence and experience of Hosokawa on this sector.

Fig.2 Isolator compatible double feed metering screw with 3 articulated arms to facilitate installation and cleaning

Terminology

A variety of different terms and abbreviations are used in the field of containment technology; here the most important ones:

Containment system (isolator):

This is understood to be a system which as a result of its concept and design serves to protect the operator against contact with active substances and which is usually realized by encapsulating the dust exposure section(s). The containment system is characterized by a housing operated under negative pressure.

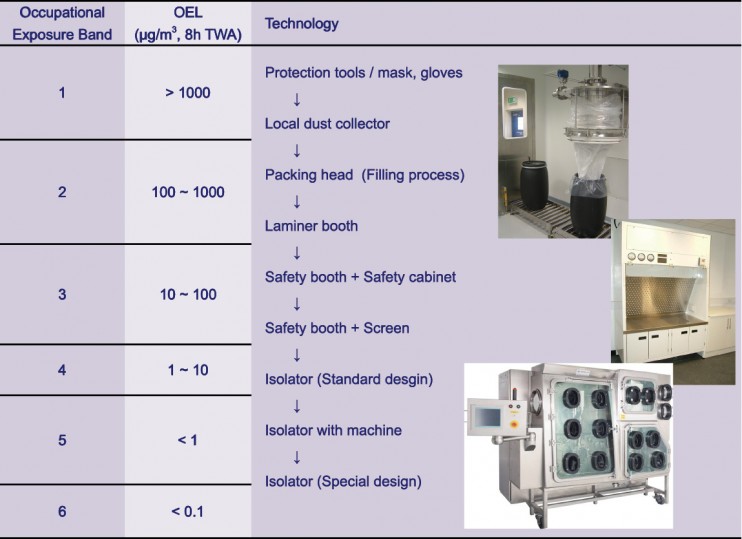

OEL:

When processing powders, product particles inevitably escape into the environment. The maximum permissible product concentration in the ambient air in the context of personnel safety is given in weight/air volume, whereby an average value of over 8 h/day is assumed. This limit value is defined as the "Occupational Exposure Level" or OEL for short. Note: typical values are meanwhile in the range of a few µg/m3 up to several nanograms/m3. Most companies have defined suitable protection measures related to different OEL values, which should be employed to ensure adherence to the limit concentration values.

HEPA filter (High-Efficiency Particulate Air filter):

The working zone of an isolator is subject to a constant gas exchange. As the gas exits the isolator, it must be cleaned thoroughly to remove the active substance particles, which is where these highly efficient filters come into their own. HEPA filter classes are defined in accordance with EN 1822-1.

Safe-change filter:

These filters are, in principal, final particle filters for process gases or exhaust air. There are three methods that can be applied for the contamination-free exchange of the filter elements:

- Push-push filter:

The contaminated filter element is simply pushed out of the housing as the new filter element is pushed in. Operation is from the clean side, whereas the contaminated element is pushed out towards the processing machine/isolator. - Bag-in bag-out:

The filter element is removed in a plastic bag fixed to a changing frame by means of a double O-ring. The bag is tied twice or welded closed, and the hermetically sealed bag with filter element is then separated from the housing. The new filter element is installed in reverse sequence. - RTP system:

Rapid Transfer Port systems facilitate the low-contamination inward and outward transfer of product containers or system components into and out of containment systems. The double door cannot be opened until the container is docked and locked in place.

Split butterfly valve:

This double flap valve system basically corresponds to a disc valve comprising two disc halves; one disc half as the active section with drives, the other as the passive section. The active section is fitted to the stationary module, the passive section to mobile bins. If the two halves are brought together, low-contamination product transfer is possible once the two disc halves have been locked into place.

SMEPAC (Standardized Measurement of Equipment Particulate Airborne Concentration):

Standardization initiated by ISPE of measuring methods to determine the achievable OEL values of containment equipment.

Filter integrity test:

as per ISO 14644-3 to test filters in installed condition for correct installation and leak-free seating. DEHS (Di(2-ethyl-hexyl)-sebacate) is typically used as the test aerosol.

Isolator standards:

ISO 10648-2 describes the classification of safety vessels in accordance with the sealing integrity and related test methods. The ISO distinguishes between four classes as a function of a defined leakage rate.

Mock-up:

A mock-up is understood here to mean a prototype of an isolator system (usually made of wood) which makes the characteristics of the later system visible and tangible at an early development stage. It serves to determine the final number and position of the glove openings.

Table 1 Category of containment technology

Packing Head system:

Containment Level 100 - 1000 μg / m3

Fig.3 Packing head system

Laminar Flow Booth:

Containment Level 100 - 1000 μg / m3

Fig.4 Laminar booth

Safety Booth:

Containment Level 10 - 100 μg / m3

Fig.5 Safety booth

Isolator:

Containment Level 0.01 - 10 μg / m3

Fig.6 Isolator

Related equipments

Feel free to contact us. if you have any questions or concerns.