- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Picoline

Picoline

Summary

Among Hosokawa product line, typical equipment (mills, classifiers, mixers) have been scaled down to tabletop models: Picoline. With common platform, different modules can be attached. For the purpose of R&D work, the research engineers can try out 10 different unit operations in the industries of pharmaceutical, chemical, battery, magnet, ceramics, food and Nano technology.

Features

Small sample processing

It is possible to process one to a few gram samples for milling, classifying, mixing and particle designing with 10 modules. CHemical hazard mateial can be processed within the continment techonoly, picocont.

Minimizing scale-up risk.

Products from the Picoline are corresponding to those of production scale model.

R&D purpose

The Picoline adopts module system and consists of 3 main components.

Platform

The platform can be attached with all modules (pico-cont is not included). Platform is provided with touch-panel control unit and the connections for electricity, water and compressed air.

Function Modules

Various modules are provided; classifier head, housings, mills and motor adapters.

Accessories

Feeder and dust collectors (for short test + for continuous operation) are provided for each module.

Fig.1 picocross

Fig.2 picoplex

Fig.3 picojet in continuous operation

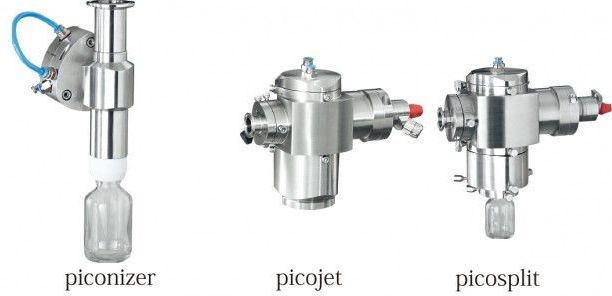

| piconizer | picojet | picosplit |

|---|---|---|

| Spiral jet mill | Fluidized bed opposed jet mill | Air classifier |

|

|

|

|

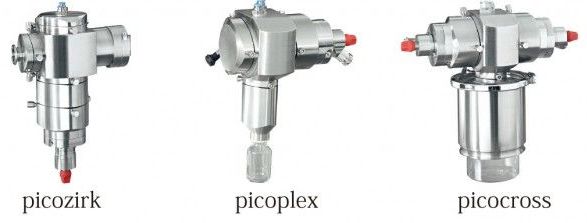

| picozirk | picoplex | picocross |

|---|---|---|

| Impact mill integrated with air classifier | pin mill | pin mill equipped with two opposing rotating pin discs |

|

|

|

|

| picoliq | picobond |

|---|---|

| Wet beads mill | Particle design (dry particle coating) |

|

|

|

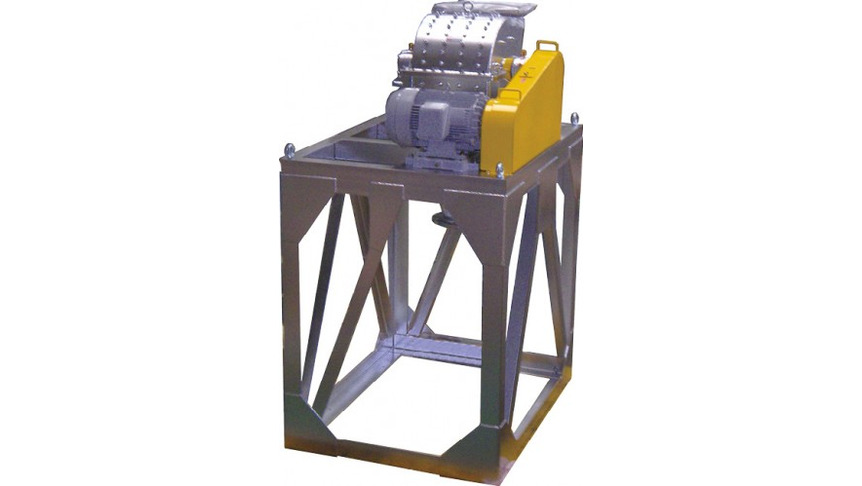

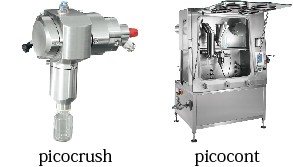

| picocrush | picocont |

|---|---|

| For premilling | Isolator integratyed system |

Related equipments

Feel free to contact us. if you have any questions or concerns.