- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- GLACIS GC

GLACIS GC

Summary

The Glacis is a high performance cooling type fine grinding mechanical mill that can grind heat-sensitive materials comparable to product sizes produced by jet mills. The Glacis has energy consumption levels lower than jet mills.

In conventional systems, the jet mill was mainly used to grind toner while preventing the materials from melting due to the heat generated during grinding. While the jet mill is an effective from of grinding, lately mechanical grinding processes are being considered once again due to the high-energy consumption and low product yield of the jet mill. To meet these user needs, in 2011, Hosokawa succeeded in developing a high performance cooling type fine grinding mechanical mill. Large production scale units have already been sold, with confirmation of high quality products being produced. From the unique features of being able to ultra-fine grind products while having a high performance cooling mechanism, the Glacis is a well-suited machine for grinding toners, tea leaves, plastics, and other heat-sensitive materials.

(GLACIS is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

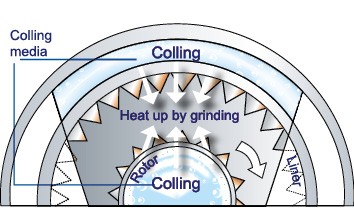

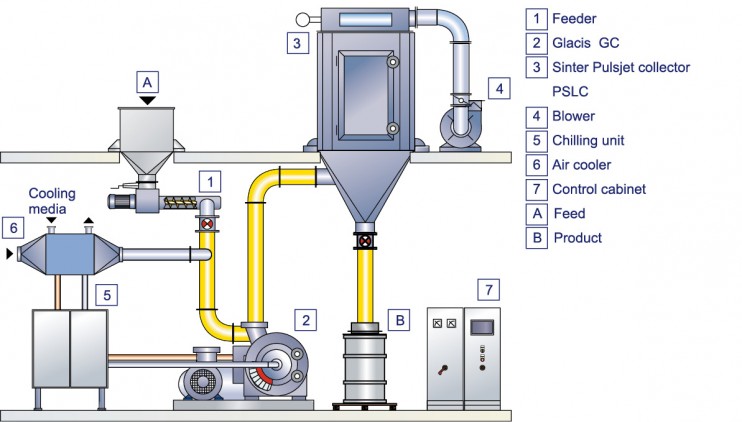

The rotor and liner within the grinding section have a special design that allows efficient cooling. The raw material is first carried to the grinding chamber by the chilled air. Once it reaches the grinding chamber, the strong impact and shearing force generated in between the small space of the chilled multi-staged gear shaped high-speed grooved rotor and the grooved liner chilled by a jacket structure, grind the material to ultra-fine levels. The ground products are then discharged from the outlet located on the opposite side of the inlet, and are collected by the cyclone or bag filter connected to a blower.

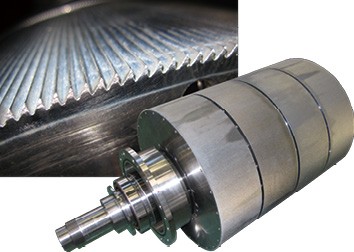

The unique grinding chamber design allows the Glacis to achieve product sizes close to ones produced by jet mills even if it is a mechanical type mill. Through extensive research for finding the optimal chilling structure, we were able to increase surface area by making the grinding rotor multi-staged, and increase-cooling efficiency compared to other similar units.

Fig.1 Toner

Fig.2 Structure

Fig.3 Grinding Rotor

Features

Fig.4 Glacis GC-600

Ultra-fine grinding of heat-sensitive materials

Suitable for grinding heat-sensitive resins due to its high cooling efficiency.

When grinding toner, the Glacis can produce products with the same average particle size (approximately 5μm) as products produced by jet mills.

Energy-saving

Compared to the jet mill, the Glacis has 50% lower energy consumption as a system.

Superior cooling efficiency

The Glacis was able to achieve a high cooling efficiency (7.5 times more than the conventional mechanical mill) by running coolants through the outer liner and grinding rotor. The Glacis can ultra-fine grind low-melting point, heat-sensitive materials that we impossible with conventional units.

Compact design of the unit and system

Due to the fact that the Glacis has a low air volume requirement relative to grinding power, additional auxiliary equipment such as the blower and bag filer can be scaled down, allowing for a compact installment.

Production scale test units

Small, medium, and large-scale units of the Glacis are available for tests at our test center, allowing us to check the product characteristics and scale up possibilities at the production level.

Applications

The unit is suitable for heat-sensitive materials such as toner and powder paints, as well as tea leaves, etc. which can lose aroma due to heat exposure.

Fig.5 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.