- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- NAUTA MIXER Vacuum/Pressure type

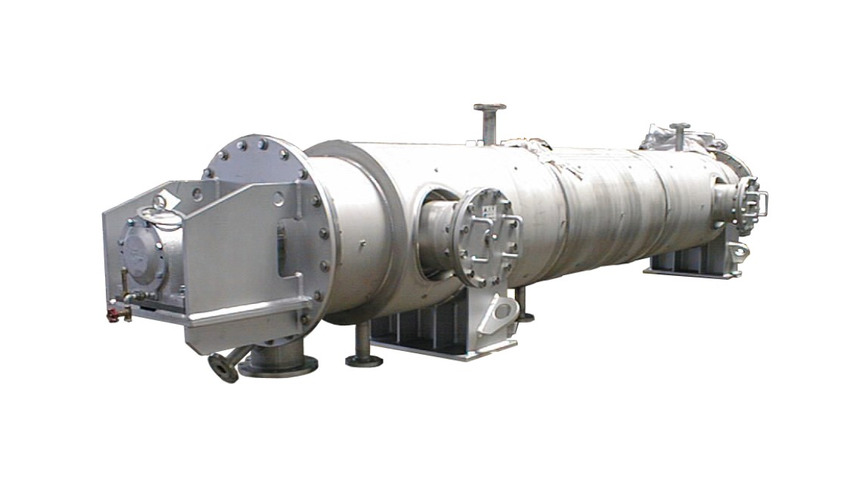

NAUTA MIXER Vacuum/Pressure type

Summary

Taking advantages of Vrieco-Nauta Mixer's superior mixing functions, vacuum/pressure type is so designed that operations of vacuum drying, reacting, heating, cooling and sterilizing are possible. Since applicable range is wide, it is very stuiable for rationalization of the production process and labour saving.

(NAUTA & "NAUTA MIXER" is a registered trademark of HOSOKAWA MICRON CORPORATION in Japan)

Principle

Fig.1 Schematic structure

Fig.1 shows the structure of the Vrieco Nauta Vacuum Dryer. Basic construction is the same as the standard Vrieco Nauta Mixer. The difference is that the orbit arm, screw shaft seal and conical vessel itself and designed for vacuum tight (In case of pressurized operation/reactor use, pressure tight construction). The jacket is provided on the casing for the heating medium such as steam or hot water. Heated casing is used as a heat transferring area. This is the indirect heating/drying, which the material does not directly contact with the heating media.

Features

High heat transfer coefficient.

Depend on material. Normal U=50-2000W/(m2•K).

Low energy consumption.

ca. 5.5-13kW for 2,000 liter/batch.

Limited air tight part.

Structurally, it has smaller airtight part. Negligible air leakage and stable vacuum condition is maintained. Small vacuum pump.

Easy discharge and less remaining product in the vessel.

Conical casing with discharge port at the bottom. Product discharge is easy and less residue remaining.

Easy to clean

A simple machine structure with one screw inside a vessel allows for easy cleaning. This makes changing products easier and maintenance is also simplified.

Dust protection

As pulsjet vacuum collector (HP type) is directly mounted on the vessel, it protects condenser and vacuum pump from dust.

Applicable to various processes

It can be used for mixing, drying, reaction and cooling on purpose.

Sealing is free from the powder

As the drive unit is located at the top of the machine, there is no need for seals to be in the powder bed. This prevents the seal from damage by wearing.

Fig.2 Flow

Related equipments

Feel free to contact us. if you have any questions or concerns.