- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Hosokawa Micron Group "Basic Policy on the Environment"

- Management Philosophy

- Corporate Overview

- Executive Officers

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- Industries & Machines

- Machines Search

- Multi-processing System

Multi-processing System

Summary

The task of laboratories or development centers is usually the manufacture of small amounts of product samples for tests with the aim of defining an industrial manufacturing process. The laboratory-scale systems must offer process reproducibility and the possibility of scaling up at a later date to production-scale equipment.

Multi-processing system for 5 processes, also suitable for CIP/SIP procedures:

A) Opposed jet mill 100AFG.

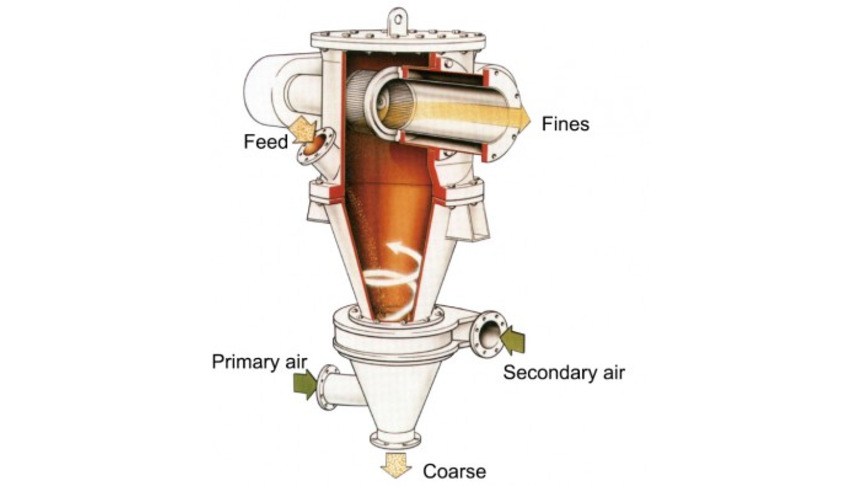

B) Ultrafine classifying with the 50ATP.

C) Fine impact mill with integrated 50ZPS classifier.

D) Spiral jet mill 100 AS.

E) Fine impact mill 100 UPZ.

Principle

Because grinding properties of new product cannot always be predicted in advance they have to be constantly being developed, maximum flexibility is required. This is why so-called multi-processing systems have established themselves as veritable all-rounders: it takes only a few minutes to exchange the following modules:

- Opposed jet mill AFG

- Ultrafine classifier ATP

- Classifier mill ZPS

- Spiral jet mill AS

- Fine impact mill UPZ

This concept revolves around the fact that the installation frame, the feed metering unit, the valves for bearing rinsing air and grinding air, the drive, the product collection filter, the fan, the electric and the control unit are common to all processes.

The latest development is the extension of this combination system by a fine impact mill, which can be equipped with the standard variety of grinding elements (pin discs, plate beater units, grinding tracks, sieve grates, etc.). A newly developed drive, controlled by a frequency converter with different sets of parameters permits (in spite of the very different design, power and speed) installation of both the grinding rotor of the fine impact mill and also of the deflector-classifying wheel.

Features

Jet milling with the Alpine fluidized bed opposed jet mill AFG

Fig.1 100AFG

- For materials with a Mohs' hardness up to 10.

- Fineness values of d97 = 2 to 40 µm.

- End products with steep particle size distributions and free of oversized particles.

- The use of PU elements results in end products with no iron contamination.

Classifying with the Alpine Turboplex ultrafine classifier ATP- For materials with a Mohs' hardness up to 10.

Fig.2 50ATP

- Separation/fineness range steplessly adjustable from d97 = 2 to 80 µm.

- Extremely high precision of cut.

- End products with steep particle size distributions and free of oversized particles.

- Ideal for materials of high density.

- Good dispersion of cohesive products.

Fine grinding with integrated Zirkoplex classifier mill ZPS

Fig.3 ZPS

Ultrafine grinding with the Aeroplex spiral jet mill AS

Fig.4 AS

Fine grinding with the fine impact mill UPZ

Fig.5 UPZ

Related equipments

Feel free to contact us. if you have any questions or concerns.