- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- About Us

- Technical Information

- Details of Agglomeration Technology

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

-

Technical Information

- Summury of Powder Technology

- Details of Millling technology

- Details of Classification Technology

- Details of Mixing/Blending Technology

- Details of Particle design Technology

- Details of Agglomeration Technology

- Details of Drying Technology

- Details of Dedusting Technology

- Details of Measuring Technology

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Details of Agglomeration Technology

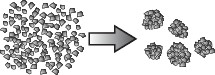

In general, the finer the powder, the worse its flowability becomes. In addition, their apparent density becomes lighter, making them bulkier and more difficult to disperse. In order to improve these powder characteristics, agglomelation is used to gather small powders and make them larger.

Agglomeration method

Depending on the purpose, different methods such as compression molding, wet granulation, extrusion granulation, and agitation granulation are used. For example, instant foods require immediate dissolution, agricultural chemicals and fertilizers require sustained release, and carbon black requires improved dispersibility.

For example, in the case of instant foods, wet agitation granulation is used for a very short time to produce granules with many gaps between the powders. This allows the warm liquid to enter the gaps, making it easier to dissolve.

Agglomeration methods can be broadly divided into dry granulation and wet granulation, and it is necessary to select the appropriate granulation technology depending on the apparent density and particle size distribution required for the product.