- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

- TOP

- About Us

- Technical Information

- Details of Mixing/Blending Technology

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

-

Technical Information

- Summury of Powder Technology

- Details of Millling technology

- Details of Classification Technology

- Details of Mixing/Blending Technology

- Details of Particle design Technology

- Details of Agglomeration Technology

- Details of Drying Technology

- Details of Dedusting Technology

- Details of Measuring Technology

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Details of Mixing/Blending Technology

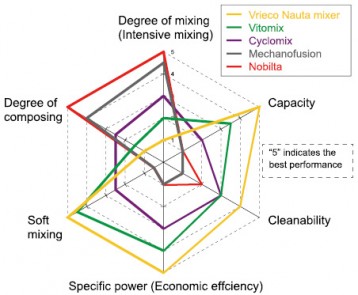

Mixing is a process where two or more materials are mixed together. There are many methods to express the level of mixing and there are also many evaluation methods. This results in experience being a major factor in the selection of a mixer. The required level of mixing differs between if the mixed material is a raw material, intermediate material or a final product. Another important factor is the unit volume of mixed material used in the product. When selecting a mixer, it is better if the selection is based upon the quality control method in use. Hosokawa has a line-up of multiple mixers and can provide an optimum process based on the following selection criteria.

Evaluation of mixing/blending and selection of equipment

There are many different ways of expressing and judging the state of mixing, and the selection of a mixer depends largely on experience.

The optimum mixing method depends on whether the mixture is a raw material preparation, an intermediate product, or a final product, and is also greatly influenced by the physical properties of the mixture. In selecting a mixer, it is common practice to select one based on the quality control standards of the product.

As for scaling up, power and mixing time are the main issues. The power is almost proportional to the input weight, but care must be taken with powders that have particularly high bulk density, or with powders that have a large difference between loose bulk density and hardened bulk density.

The mixing time basically depends on the average time it takes for the powder to circulate in the mixer, but it can also be determined empirically by adding actual values.

Also, when handling the powder after mixing is complete, care must be taken to prevent segregation and separation.