- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

About Us

- TOP

- About Us

- Technical Information

- Summury of Powder Technology

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

-

Technical Information

- Summury of Powder Technology

- Details of Millling technology

- Details of Classification Technology

- Details of Mixing/Blending Technology

- Details of Particle design Technology

- Details of Agglomeration Technology

- Details of Drying Technology

- Details of Dedusting Technology

- Details of Measuring Technology

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Summury of Powder Technology

What is the powder technology?

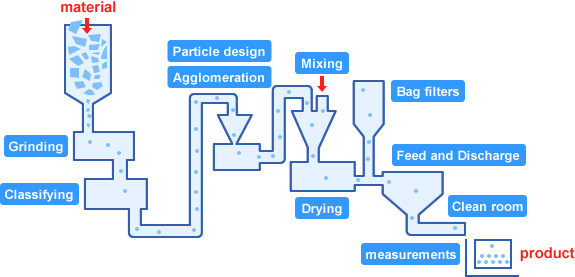

The powders technology is indispensable to the production of industrial products. The following is the schematic view of the process consisting of 10 unit operations.

Explanation of the schematic view

Above 10 unit operations cover various working principles, mechanism, and machines. The economy and effective manufacturing of powdery product is possible by selecting the most appropreate machine and operating condition for your targeted material and purpose. Hosokawa Micron systematizes hardware required for individual operation and adds accumulated know-how and software to the system. Hosokawa Micron provide “Total engineering service of powder”

Powder technology for your benefit?

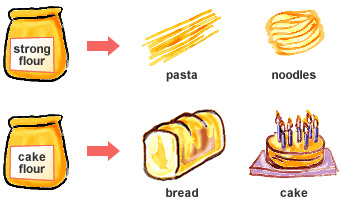

Speaking of powder, many people seem to image wheat flour. This will be because there are many opportunities to see it in daily life. Of course, as for the use of the wheat flour, as for the noodles, the bread, the cake, various. Depending on those uses, the particle size and protein cotents are controlled. In order to meet such an adjustment, powders technology such as amilling, classification and mixing is used..

If one looks around the daily life, it begins to food such as spice, the instant coffee a little and may be easy to image the cosmetics such as foundations having condyle granulation, tablet-formed pharmaceutical products, a UV cut function as an object of powders technology.

What is your impression of the world of powder?

Powders technology is the technique that is very important at the stage of raw materials or the intermediate product to draw a characteristic necessary for an end product. It may be said that it is a technique needing by every industry transversely. The powders technology is to be conjugated widely by an advanced technique to develop new material from our surroundings thing. The object is regarded as important by the emerging technology mainly on the technology now.It may be said that there is not the scientific progress without the progress of the powders technology.Hosokawa Micron opens up the future of the 21st century by powders technology, process technology.