- Industries & Machines Industries & Machines

- IIoT IIoT

- Service-Toll Processing Service-Toll Processing

- Material Material

- News News

- IR Information IR Information

-

Sustainability

Sustainability

Sustainability

- Introduction

- Hosokawa Micron Group "Basic Human Rights Policy"

- Sustaibality Policy - Mission Statement

- Editorial Policy

- Integrated Report

- Materiality & Strategy

- Technological contribution to a sustainable global environment

- Contributions towards a safer, more secure and prosperous society

- Sophistication of governance that supports business

- ESG Data Collection

- Sustainable Business Management ~ Finance

- Infromation Disclosure Based on TCFD Recommendations

- Jobs and Careers Jobs and Careers

-

About Us

About Us

About Us

- Greetings (Company Introduction)

- Hosokawa Micron Group "Basic Human Rights Policy"

- Management Philosophy

- Corporate Overview

- Corporate Profile

- Business Areas and Strengths

- Corporate History

- Hosokawa Micron Group

- Domestic Facilities

- Overseas Subsidiaries (Asia)

- Overseas Subsidiaries (Europe)

- Overseas Subsidiaries (America)

- Asian Agents

- Powder Technology Research Institute

- Industrial Property Rights

- Journals and Books

- Technical Information

- Annual Publication "Micromeritics"

- Compliance Charter

- Privacy Policy

- Cookie Policy

- Quality Principle

Industries & Machines

Filler

Summary

The fillers that were considered ultrafine just a few years ago are now standard products. The filler market may be large but it is also fiercely competitive. The requirements are therefore either fine fillers with a sharp top cut at low costs or custom-made particle size distributions.

Contents

These specifications are not sufficient to enable selection of the optimum system, however – instead, it is necessary to consider the different products and their properties, e.g. the laminar structure of talc, the microcrystalline structure of chalk, etc. The maintenance costs, product change and space requirement, to name just a few aspects, must also be taken into consideration.

Fine fillers – high performance

Fig.1 Super Orion Ball Mill S.O.

Limestone (CaCO3) is one of the most important, versatile and – in terms of quantity – most frequently used minerals. It is common throughout the world and is used in the plastics, rubber, foodstuffs, chemical and pharmaceutical industries.

Our solution for this application is a large S.O.

300/600 ball mill in circuit with a Turboplex classifier 630/4 ATP, paired with an efficient control unit with in-line particle size analysis to control the fineness.

Although dolomite – similar to limestone and calcite – is also used for ultrafine fillers, the main customers are the glass, ceramics and steel industries, who demand medium-fine products or even steep particle size distributions.

Ball mill Super Orion S.O.-SF (superfine)

Fig.2 Load cell

This system combines the robustness of a ball mill with a high-efficiency ultrafine classifier. The direct pneumatic transfer of the feed material into the classifier saves on the necessity for susceptible conveying units and guarantees an extremely compact, inexpensive configuration. The modern control unit and the in-line particle size analysis unit make it possible to run the system for several shifts without personnel. This solution has enabled our customers to secure substantial market advantages for themselves.

Agitating ball mill with multi-wheel classifier

Fig.3 ATR system (agitating ball mill)

Hosokawa/Alpine ATR agitated ball mills are absolutely ideal for the dry production of superfine mineral powders of less than 10 µm in size. Fineness values to 95% < 2 µm with a high specific surface can be obtained. The ATR technology ensures optimum energy utilization at maximum system reliability. The combination of these process qualities guarantees extremely cost-effective operation.

Table roller mill AWM

Fig.4 Table roller mill AWM for bentonite grinding

Table roller mills are robust and proven mills for medium-hard mineral raw materials and industrial bulk goods. They are characterized by their compact design, high throughput rates and low energy requirement.

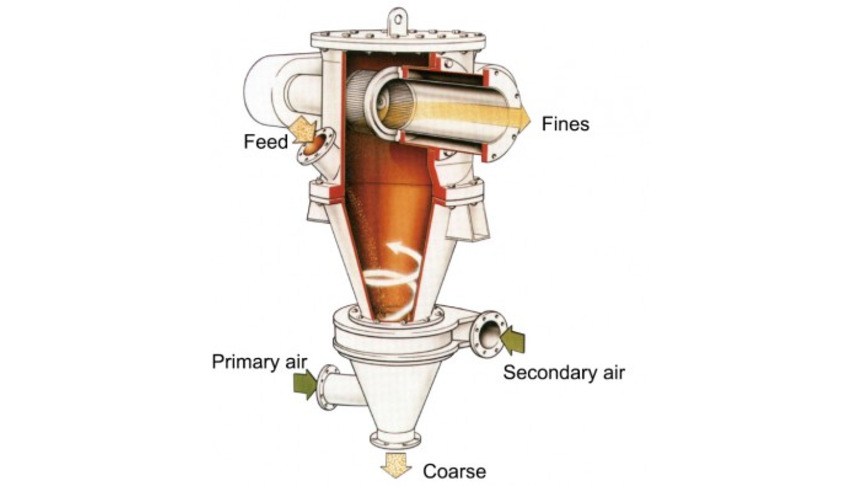

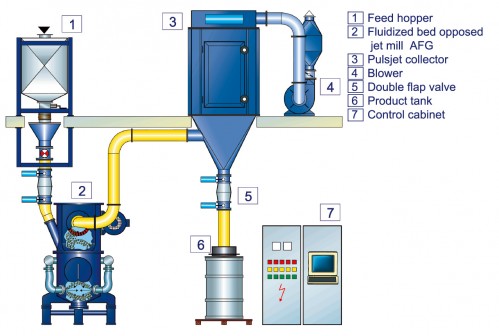

Fluidized bed opposed jet mill AFG

Fig.5 710/4 AFG with ATP multi wheel classifier

Typical for the employment of the AFG is the fineness range d97 = 5 to 20 µm and the requirement for contamination-free, i.e. iron-free, grinding. The AFG also has an extremely good delaminating function at optimum retention of the laminar structure, e.g. talc or mica.

Talc

Compared with limestone, talc is a specialty within the filler market. Because there are numerous types of talc that vary widely dependent on the individual deposit, both the processing and the application of this raw material are extremely diverse.

Talc has the following features:

- Plate-like, laminar structure

- Low hardness value

- Insoluble in water

- High degree of whiteness

- Chemical stability

Thanks to these properties, talc is mainly used in the following two application areas:

Paper industry:

As a coating pigment and to permit pitch control

Plastics sector:

As a filler for polypropylene, to increase the rigidity and the dimensional stability special applications can be found in the cosmetics, pharmaceutical and ceramic industries.

There are two things, which require special attention when processing talc: the high abrasiveness of the contaminants (quartz, dolomite, etc.) in the otherwise soft talc, as well as preservation of the laminar structure. Because of this, we mainly employ the AWM table roller mill, AFG fluidized bed opposed jet mill or the Zirkoplex classifier mill ZPS for grinding talc.

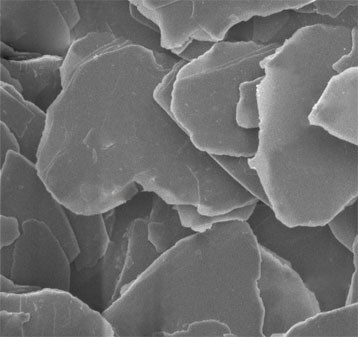

Fig.6 Example of laminar structure

Fig.7 Table Roller Mill AWM with Turboplex

Hosokawa/Alpine fluidized bed opposed jet mill AFG has become a standard the world over for ultrafine grinding. Employment of a multi-wheel classifier in the AFG jet mill allows high fineness values at high throughput rates to be achieved. This is the reason why our large jet mills (800/3 AFG and 1250/6 AFG) are in use by all market leaders on the talc sector. The new 1500/3 AFG – the world's largest jet mill – has made it possible to significantly extend the throughput. All machines are equipped with patented mega-jet nozzles and operate with hot compressed air to boost performance.

Fig.8 The world's biggest fluidized bed opposed jet mill 1500/3 AFG

Fig.9 Flow of AFG

Fig.10 Floating mineral powder by coating

Perlite

“Functional fillers” are used for plastics, paints and varnishes and also in the construction industry for insulating material and admixtures for lightweight concrete in order to retain specific characteristics of the finished material in the application. For example, expanded perlite is used as filler in paints and varnishes due to its special properties, it ensures the following positive features:

- Low filler quantities required

- Free from crystalline quartz

- Low bulk densities

- Paint dries quicker

- In part a substitute for TiO2

Coating mineral powders

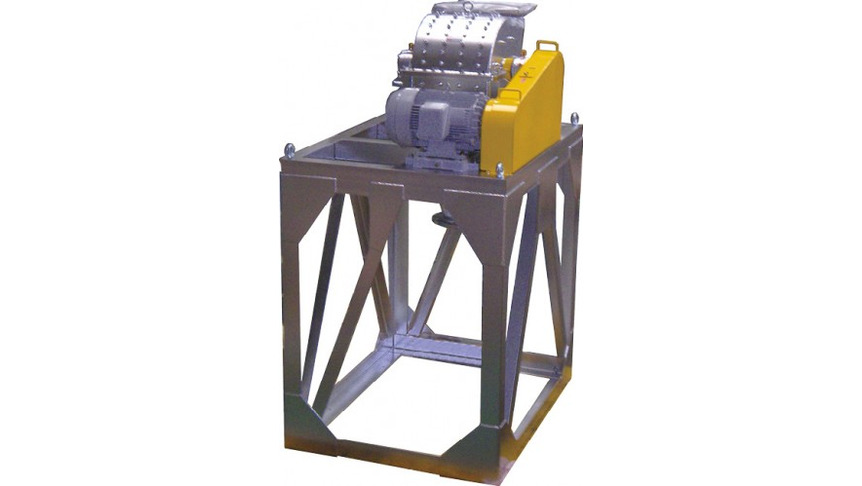

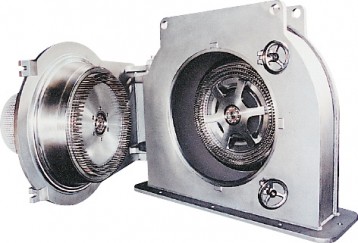

Contraplex pin mills have been used for the surface treatment of mineral powders for many years. The most frequent application is the coating of fine, natural calcium carbonate powder by means of technical stearic acid. Other applications are the coating of talc and kaolin, whilst salines are mostly used for surface treatment.

Such surface-treated minerals are able to create a firm bond between the mineral powder and a polymer. The resultant surface-treated fillers are used, for example, in plastic profiles, PVC pipes and in automotive parts not just as fillers but also because of the improved properties such as impact strength.

Decisive for the quality when coating calcium carbonate is optimum temperature control throughout the entire process and the constant metering of the coating agent and mineral powder. Our newly developed melting unit for coating agents has been able to optimize the process even further. The melted coating agent is sprayed through a two-component nozzle and mixed with the mineral powder in a primary bin. Thanks to the intensive mixing in the Contraplex pin mill and the optimum temperature control, an excellent coating quality is achieved. The system is operated by means of a modern PLC unit with visualization.

The long gap mill LGM has proved itself in service for coating the much finer precipitated calcium carbonate PCC.

Both processes permit – in contrast to batch operation – continuous production operations at maximum product quality, i.e. no uncoated material, no lumps or agglomerates.

Fig.11 Contraplex 800CW

Fig.12 Long Gap Mill LGM-3

Limestone (dry and wet grinding)

Most fillers outside of the paper industry are used in dry form. It therefore makes sense to manufacture these products in a dry process. In the case of ultrafine fillers, however, one soon reaches the physical and above all economic limits. Limestone, the foremost raw material, can be dry-processed to a fineness of 2 µm (dependent on the microcrystalline structure, hardness, etc.). The dry agitated ball mill ATR in combination with the TTD Turbo Twin Double classifier is used for this task.

Because of the high energy and grinding aid consumption, however, this is no longer an economic solution. It is much more effective to use an ANR wet mill for such requirements and to subsequently dry the product in an LGM long gap mill.

The system schematic shows a system designed for the production of limestone slurry without a downstream long gap mill to dry the slurry. A dry preliminary crushing step with Hosokawa/Alpine AWM table roller mill can be configured upstream of the system.

Related equipments

Feel free to contact us. if you have any questions or concerns.